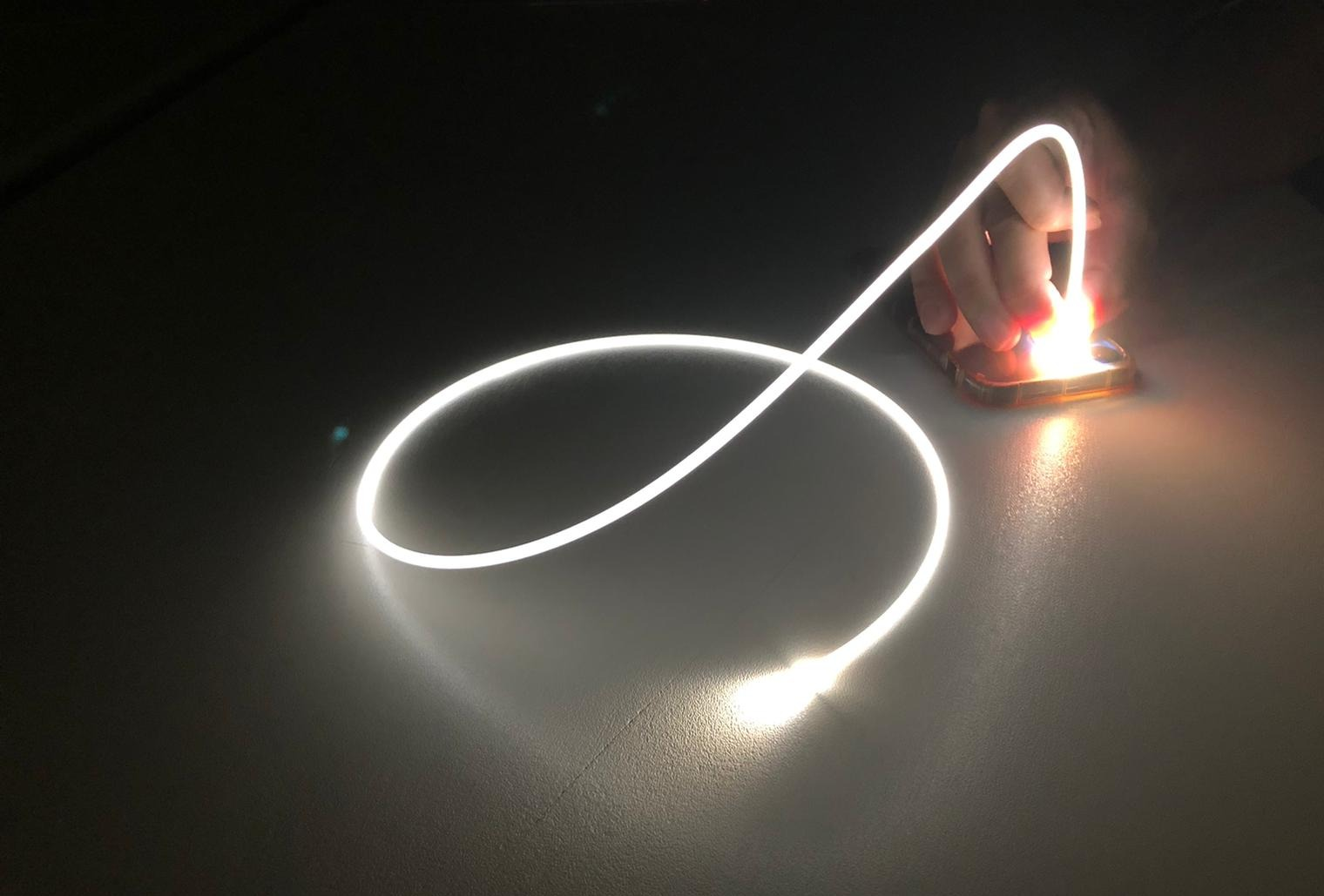

Q: Introduction of Automtive Light Guide Rod Automtive light guide rod are a kind of decoration with linear lights, which are often installed on cars. This decorative item can bring a unique visual effect to the car, improve its recognition and safety,

and can also create a unique atmosphere for the car interior. Automtive light guide rod usually consist of one or two LED lights and soft light guide strips, which can be installed in headlights, taillights, door edges, and under the body of the car. According

to different needs and scenes, different colors, brightness, flashing modes, etc. can be set. For example, when the vehicle brakes, the light guide strip can automatically turn red to increase the recognition of the brake; when the vehicle is started, the

light guide strip can flash briefly to increase the visual effect. In addition, some high-end car brands will also install light guide strips in the car to create a unique interior lighting effect and enhance the riding atmosphere. In the past, Automtive light

guide rod were only used as car decoration, but now more and more vehicle manufacturers have taken them into consideration in car design and become a part of car safety design. The light guide rod can improve the driver's recognition of the vehicle at night

or in low visibility conditions, reducing the risk of accidents. In addition, the light guide rod can also provide better visual cues for pedestrians and other vehicles, enhancing driving safety. With the continuous advancement and application of science

and technology, automotive light guide rod are also constantly developing and innovating. Now, some high-end car brands have begun to use more intelligent technologies, such as voice control, gesture control, etc., to make the use of light guides more convenient

and intelligent. At the same time, the lighting effects and colors of the light guide rod have also been continuously improved and innovated, making the visual effects of the car more colorful. However, at the same time, it is also necessary to pay attention

to the use restrictions and safety risks of vehicle light guide strips. For example, in some countries and regions, the use of automotive light guides is restricted or banned because it may interfere with the vision of other drivers or pedestrians. In addition,

excessive use of light guide strips may distract drivers and even lead to accidents. Therefore, when using light guide rod for vehicles, you should abide by relevant local laws and regulations, use them in moderation, and pay attention to safety. At the

same time, manufacturers also need to pay attention to quality and safety in the process of product development and manufacturing to ensure product stability and reliability. Q: Types of light guide strips for vehicles Light guide strip is a lighting element

widely used in automobile exterior design. They are usually used to decorate the front and rear lights of the vehicle, and can make the vehicle more bright and eye-catching when driving at night, the following are some common types of light guide strips for

vehicles: Monochrome light guide rod: Monochrome light guide strips can only emit a single color of light, usually white or blue. Multi-color light guide rod: The multi-color light guide strip can emit a variety of different colors, and the color and brightness

can be changed by remote control or mobile APP control. Rainbow light guide rod: The rainbow light guide strip is a kind of changing and colorful light guide strip, which can change colors automatically, and the effect is very cool. Two-color light guide

rod: The two-color light guide strip can emit two different colors of light at the same time, usually white and yellow, and can be used as car daytime running lights and turn signals. Flowing water light guide rod:Flowing water light guide strip is a light

guide strip with flowing water effect, which can simulate the effects of flowing water, breathing, marquee and so on. Door light guide rod: The door light guide strip is a light guide strip installed under the door, which can be used to illuminate and decorate

the vehicle, and can also improve the recognition of the vehicle. Q: Selection key points When choosing a light guide strip for a vehicle, you need to pay attention to the following points: 1. Clear usage requirements:Choose the type, color, brightness and

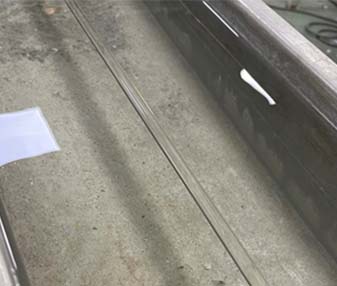

other parameters of the light guide strip according to your own needs, such as whether it is used as a vehicle atmosphere light or as a vehicle lighting lamp. 2. Appropriate size: The size of the light guide strip should match the interior space of the vehicle,

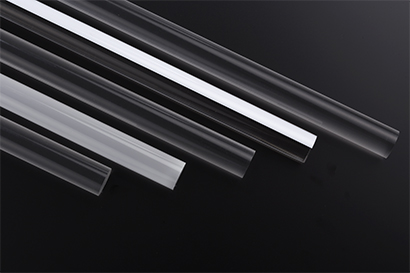

and it should not be too long or too short, otherwise the installation effect will be affected. 3. Material considerations:The material of the light guide strip needs to consider its durability, compression resistance, light transmission and other factors,

and choose the appropriate material according to your actual needs. 4. Installation method: The installation method of the light guide strip also needs to be considered. Some light guide strips can be directly pasted inside the vehicle, and some need to

be fixed and supported. It needs to be selected according to the actual situation. 5. Brand and quality: The brand and quality of the light guide strip are also factors that need to be considered when choosing. Choosing a reputable manufacturer and high-quality

products can ensure the use effect and service life of the light guide strip. In addition to the selection focus mentioned above, there are some details that need attention: 1. Waterproof level: Because the vehicle will be affected by the natural environment

such as wind and rain during driving, the light guide strip for the vehicle needs to have a certain waterproof level to ensure that it can be used normally under severe weather conditions. 2. Brightness adjustment: The brightness adjustment of the vehicle

light guide strip is also a factor that needs to be considered, because in some cases it is necessary to adjust the brightness of the light guide strip. For example, when driving at night, it is necessary to reduce the brightness of the light guide strip to

avoid affecting driving safety. 3. Control method:The control method of the vehicle light guide strip is also a factor that needs to be considered. There are many control methods for the light guide strip on the market, including remote control, mobile phone

APP, vehicle screen, etc. It is necessary to choose the appropriate control according to the actual situation Way. 4. Solder joint quality: The quality of the solder joints of the light guide strip is also very important. If the quality of the solder joints

is not good, it is easy to cause problems such as failure of the light guide strip or short circuit. In serious cases, it may cause damage to the vehicle's circuit system, so attention should be paid The solder joint quality of the light guide strip. 5.

Safety:The safety of vehicle light guide strips is also a factor to be considered, because unsafe light guide strips may pose a threat to the safety of drivers and passengers, such as circuit failures, short circuits, etc. Choose safe and reliable products.

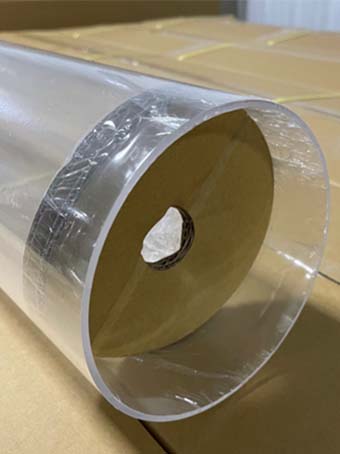

Q: Features Compared with light guide strips made of other materials, acrylic light guide strips have the following characteristics: 1. High transparency: Acrylic has very high transparency, which can allow light to pass through the light guide strip more

evenly, making the brightness of the entire light strip more uniform. 2. Excellent optical performance: the acrylic light guide strip has very good optical performance, which can well concentrate the light to the place that needs to be illuminated and improve

the lighting effect. 3. Strong durability:Acrylic light guide strips have high hardness and compression resistance, are not easy to break, and are not easy to be affected by moisture, so they can be used in humid environments. 4. Good elasticity:The acrylic

light guide strip has a certain degree of elasticity and can be bent as needed to make light strips of various shapes to meet different application requirements. 5. High safety: Acrylic light guide strips are not easy to burn, and do not contain toxic substances,

which are safe for human body and environment. Therefore, acrylic light guide strips are widely used in automotive atmosphere lights, advertising light boxes, decorative lighting and other fields. Q: Application Automotive interior light guide strips

can be used for interior decoration and lighting of vehicles to create various atmospheres and effects. The following are some application scenarios of automotive interior light guide strips: 1. Interior lighting:The interior light guide strips for vehicles

can be used for interior lighting to enhance the interior lighting effect and improve driving safety. For example, it can be installed on the edge of the door, on the roof, under the seat, etc. 2. Car atmosphere light: The car interior light guide strip

can be used as a car atmosphere light, and the color and brightness can be controlled through the remote control or mobile APP to create different atmosphere effects, such as red for enthusiasm, blue for calm, etc. 3. Audio and lighting effects:The car interior

light guide strip can be used with the car audio system to simultaneously display the rhythm and beat of the music, creating a more dynamic effect. 4. Safety reminder:The car interior light guide strip can be used for safety reminder, for example, it is

installed on the edge of the car door. When the door is opened, it can remind the surrounding pedestrians and vehicles to pay attention to avoid accidents. In short, the application scenarios of automotive interior light guide strips are very wide, which

can make vehicles more beautiful, safe and comfortable.

_1.jpg)

.jpeg)

.jpeg)