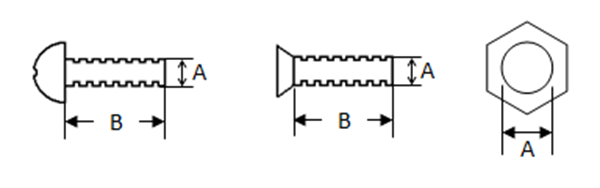

Transparent Screw and Nut

SME's transparent screw are divided into round heads and flat heads, which can be matched with the nuts. They are widely used in acrylic processing products, teaching aids, pet cages, etc.

Description

Transparent Screw and Nut Specifications

| Screw | ||||||

| A x B (mm) | 4 x 8 | 4 x 12 | 4 x 16 | 4 x 20 | 4 x 25 | 5 x 12 |

| A x B (mm) | 5 x 16 | 5 x 20 | 5 x 25 | 5 x 30 | 6 x 30 | -- |

| Nut | |||

| A (mm) | 4 | 5 | 6 |

Transparent Screw and Nut Features

• PC Material

• With more than 10 sizes

Transparent Screw and Nut Application

• Widely used in acrylic processed products, teaching aids, pet cages, etc.

Customized Acrylic Processing Service

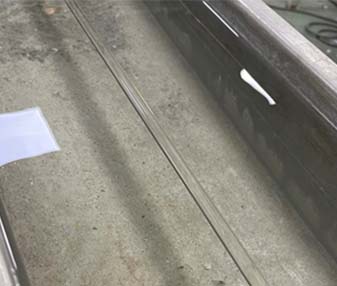

- Cutting: Cutting according to the size required by customers, the precision tolerance can reach ±0.5mm

- Polishing: Treat the acrylic surface with a diamond polishing machine to make it smooth and translucent.

- Drilling: Drilling according to customer's requirements, and it is matched with customer's sample kit.

- Bending: Bending according to customer's requirements, heating the acrylic tube, and then bending with jigs.

- Chamfering: The edge of the acrylic pipe is chamfered to reduce sharp edges.

- Printing: Print patterns, words or images onto the acrylic surface to achieve personalized decorative effects.

- Laser cutting: Using high-power laser beams for precise cutting can achieve diverse cutting needs.

- Assembly: process and assemble with the accessories required by customers to complete one continuous line service.

Not all acrylic specifications are available for the above

services, please inform us of your needs first, SMEACRYLIC will have a professional team to

evaluate for you.

About SMEACRYLIC®

- SMEACRYLIC® is a Taiwan based manufacturer which was founded in year 1980, a Professional Manufacturer in Extrusion Technology.

- We specializes in extruding various kinds of plastic Profiles, Tubes, Rods and Sheets which be used in displays, decorations, lighting, illuminated advertising, architectures and a lot more applications.

- Approximately 90% of our products are exported to over 40 countries worldwide including numerous well-known brands. Over the years, we have expanded to become the market leader in extrusion field in Asia.

QUALITY WE CARE

We insist on using 100% virgin materials.

We insist on using international branded raw materials (Sumipex, Mitsubishi, Evonik)

We insist on keeping sample records of raw materials, all raw materials are traceable.

Technical Service

SME is a customer driven company. Only

satisfied customer will ensure our

continued success. Buying goods from SME you can have a

comprehensive consulting service

package.

The following are some of the systems that we

implemented to provide our

customers with the excellent support and service.

- We developed on line catalogue for our customers.

- Stock system always offers efficient prompt delivery.

- Samples available for most of our products.

- Our home-made moulds offer fast and precision work to ensure customers' satisfaction.

- Efficient ISO-9001 managing system ensures quality stability.

Manufacturing Process

Raw material import

100% virgin material

Raw material inspection

Test raw material melt index

Pre-drying

Raw material drying, remove moisture

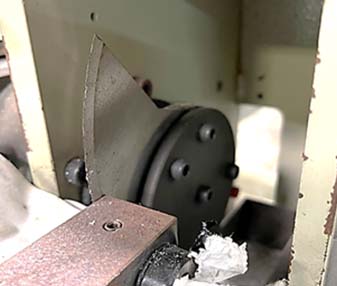

Extrusion

Shapes produced through different dies

Cooling

Cooling and shaping

Puller

Control extrusion speed

Cut to size

Cut according to the required length

Projection measure

Accurately measure via magnification

QC inspection

4 steps inspection applies during

extrusion

Packaging

Carton package to enhance product

protection

Warehousing

Instant warehousing, EPR control

Shipment

Well packed for delivery

Inspection Equipment

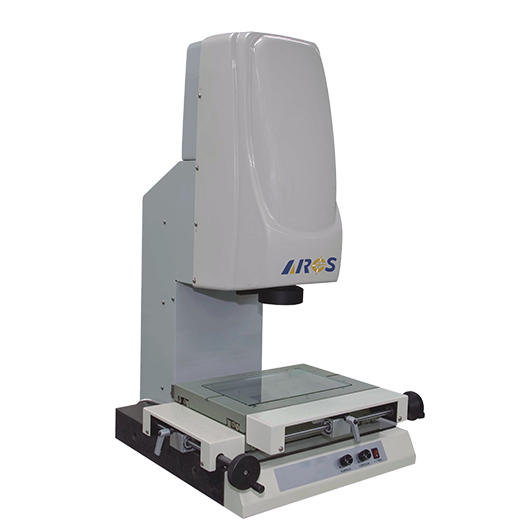

Non-contact Image Measure System

Equipped with a high-resolution and

high-precision color camera to

accurately measure the size through magnification.

Illumination Meter

Accurately measure illuminance, color

temperature, CRI, spectrogram, and

light measurement related data.

Calipers

We use Mitutoyo LCD vernier calipers from

Japan to ensure that the size

and tolerance requirements.

Melt Flow Indexer

To detect the Melt Index of raw materials

to ensure the quality and

stability of raw materials.

Moisture Analyzer

To quickly determine the free water

content of chemical raw material

samples.

Temperature & Humidity Test Chamber

Simulate the environment of high

temperature and high humidity to test the

material change and strength attenuation of our

products.

Production Equipment

Profile Extrusion Machines : 22 lines

7lines

Acrylic Rods

9lines

Acrylic Tubes

6lines

Other Profiles

3,500tons / yr

Production Capacity

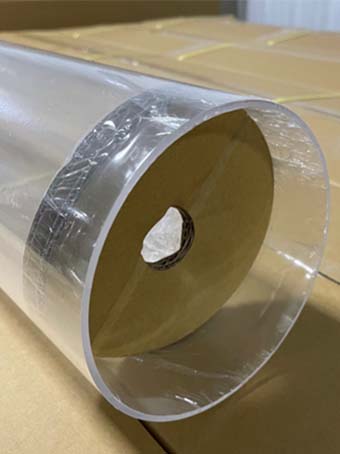

Perfect Packaging

SMEACRYLIC® packaging advantages

- Exclusive shrink film packaging slows down the water absorption of acrylic

- Giving you a good cutting experience

- Effectively avoid scratches on acrylic tube surface during cutting

- Small tubes are bundled to increase the strength and are not easy to break

- Bubble Wrap protects the tubes druing transportation

- Carton protection, convenient for warehouse management

- Square package, maximizing the storage capacity of the warehouse

ISO-9001 : 2015 CERTIFIED

International Exhibition

Related FAQ

What is Acrylic (PMMA) ?

Q: What is Acrylic (PMMA)? Acrylic is called "polymethyl methacrylate" Poly (methyl methacrylate), referred to as PMMA, also known as plexiglass, has the reputation of "plastic crystal", and is often used as a substitute for glass. 92% light transmittance,

good weather resistance, easy machining, can be adhered with chloroform, and suitable for all kinds of painting and printing (suitable for acrylic materials). The basic chemical structure of acrylic resin is acrylic acid (Acrylic acid), which is

a by-product of petroleum extraction. The scientific name of acrylic resin is Poly Methyl Methacrylate. In 1920, Rohm And Hass Company developed a synthetic resin. The chemical substance whose chemical molecular structure is CH2=CH(CH3)COOCH3 can be regarded

as an ester compound obtained by the reaction of methanol and methacrylic acid, commonly known as acrylic monomer (MMA). A monomer refers to a "chemical substance" with a "low and fixed molecular weight" that can be polymerized into a polymer of high

molecular weight, or the basic unit that constitutes a polymer. For example, methyl methacrylate (MMA), which has a molecular weight of 100.1, can be obtained as a high molecular weight homopolymer or copolymer by various polymerization techniques. Polymer

refers to high molecular weight substances, such as polymethyl methacrylate (PMMA), usually the molecular weight obtained by the casting method is greater than 1 million (Plastic pellets for extrusion and injection) Acrylic refers to a type of plastic material

that is derived from acrylic acid. It is commonly used in various applications due to its versatility and desirable properties. Acrylics can be found in both liquid and solid forms, and they are widely used in industries such as manufacturing, construction,

automotive, textiles, and art. Additionally, acrylic sheets or panels are commonly used in applications where transparency, impact resistance, and weatherability are required. These sheets can be used as a substitute for glass in certain applications like

windows, signage, displays, and protective barriers. Acrylic sheets come in various thicknesses and can be easily shaped and fabricated for specific purposes. Here are some important properties about Acrylic : Transparency: Acrylic is very transparent, similar

to glass. This makes it ideal for creating transparent or translucent products such as display windows, display boards, signage, etc. Weather Resistance: Acrylic has good weather resistance to sunlight and climate changes in the atmosphere. It is not prone

to yellowing, fading or becoming brittle due to prolonged exposure to sunlight. Lightweight: Compared to glass, acrylic is lighter. This makes it more suitable in applications requiring lightweight construction, while also aiding transportation and installation.

Ease of Processing: Acrylic is fairly easy to cut, shape, and process. This material can be produced in various forms, including sheets, tubes, profiles, etc., and can meet the needs of different shapes and sizes. Chemical resistance: Acrylic is highly

resistant to many chemicals and is not easily corroded by acids and alkalis. Therefore, it is widely used in laboratories, medical equipment, and chemical industries. Thermoformability: Acrylic can be thermoformed under certain heating conditions, so manufacturers

can make products of various shapes according to needs. Colorful: Acrylic can be dyed into various colors and has high gloss, which makes it widely used in art, decoration and other fields. Impact resistance: Acrylic is more tough than glass and has better

resistance to impact, reducing the risk of breakage. Overall, acrylic is a versatile material with diverse applications, ranging from art to industrial and commercial uses. Further Reading:PMMA V.S. GLASS