What is Acrylic (PMMA) ?

Q: What is Acrylic (PMMA)?

Acrylic is called "polymethyl methacrylate" Poly (methyl methacrylate), referred to as PMMA, also known as plexiglass, has the reputation of "plastic crystal", and is often used as a substitute for glass.

92% light transmittance, good weather resistance, easy machining, can be adhered with chloroform, and suitable for all kinds of painting and printing (suitable for acrylic materials).

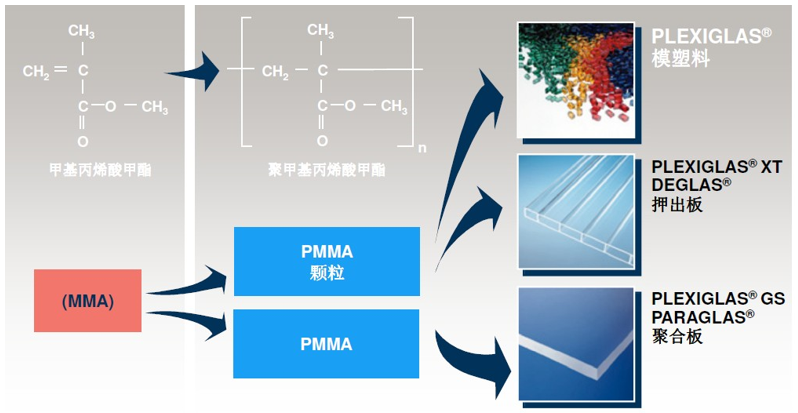

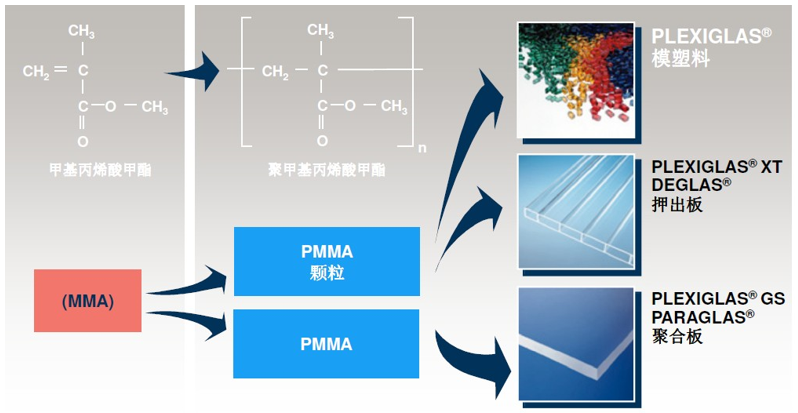

The basic chemical structure of acrylic resin is acrylic acid (Acrylic acid), which is a by-product of petroleum extraction. The scientific name of acrylic resin is Poly Methyl Methacrylate. In 1920,

Rohm And Hass Company developed a synthetic resin.

The chemical substance whose chemical molecular structure is CH2=CH(CH3)COOCH3 can be regarded as an ester compound obtained by the reaction of methanol and methacrylic acid, commonly known as acrylic monomer

(MMA).

A monomer refers to a "chemical substance" with a "low and fixed molecular weight" that can be polymerized into a polymer of high molecular weight, or the basic unit that constitutes a polymer. For example,

methyl methacrylate (MMA), which has a molecular weight of 100.1, can be obtained as a high molecular weight homopolymer or copolymer by various polymerization techniques. Polymer refers to high molecular weight substances, such as polymethyl methacrylate

(PMMA), usually the molecular weight obtained by the casting method is greater than 1 million (Plastic pellets for extrusion and injection)

Transparency: Acrylic is very transparent, similar to glass. This makes it ideal for creating transparent or translucent products such as display windows, display boards, signage, etc.

Acrylic refers to a type of plastic material that is derived from acrylic acid. It is commonly used in various applications due to its versatility and desirable properties. Acrylics can be found in both

liquid and solid forms, and they are widely used in industries such as manufacturing, construction, automotive, textiles, and art.

Additionally, acrylic sheets or panels are commonly used in applications where transparency, impact resistance, and weatherability are required. These sheets can be used as a substitute for glass in certain

applications like windows, signage, displays, and protective barriers. Acrylic sheets come in various thicknesses and can be easily shaped and fabricated for specific purposes.

Here are some important properties about Acrylic :

Transparency: Acrylic is very transparent, similar to glass. This makes it ideal for creating transparent or translucent products such as display windows, display boards, signage, etc.

Weather Resistance: Acrylic has good weather resistance to sunlight and climate changes in the atmosphere. It is not prone to yellowing, fading or becoming brittle due to prolonged exposure

to sunlight.

Lightweight: Compared to glass, acrylic is lighter. This makes it more suitable in applications requiring lightweight construction, while also aiding transportation and installation.

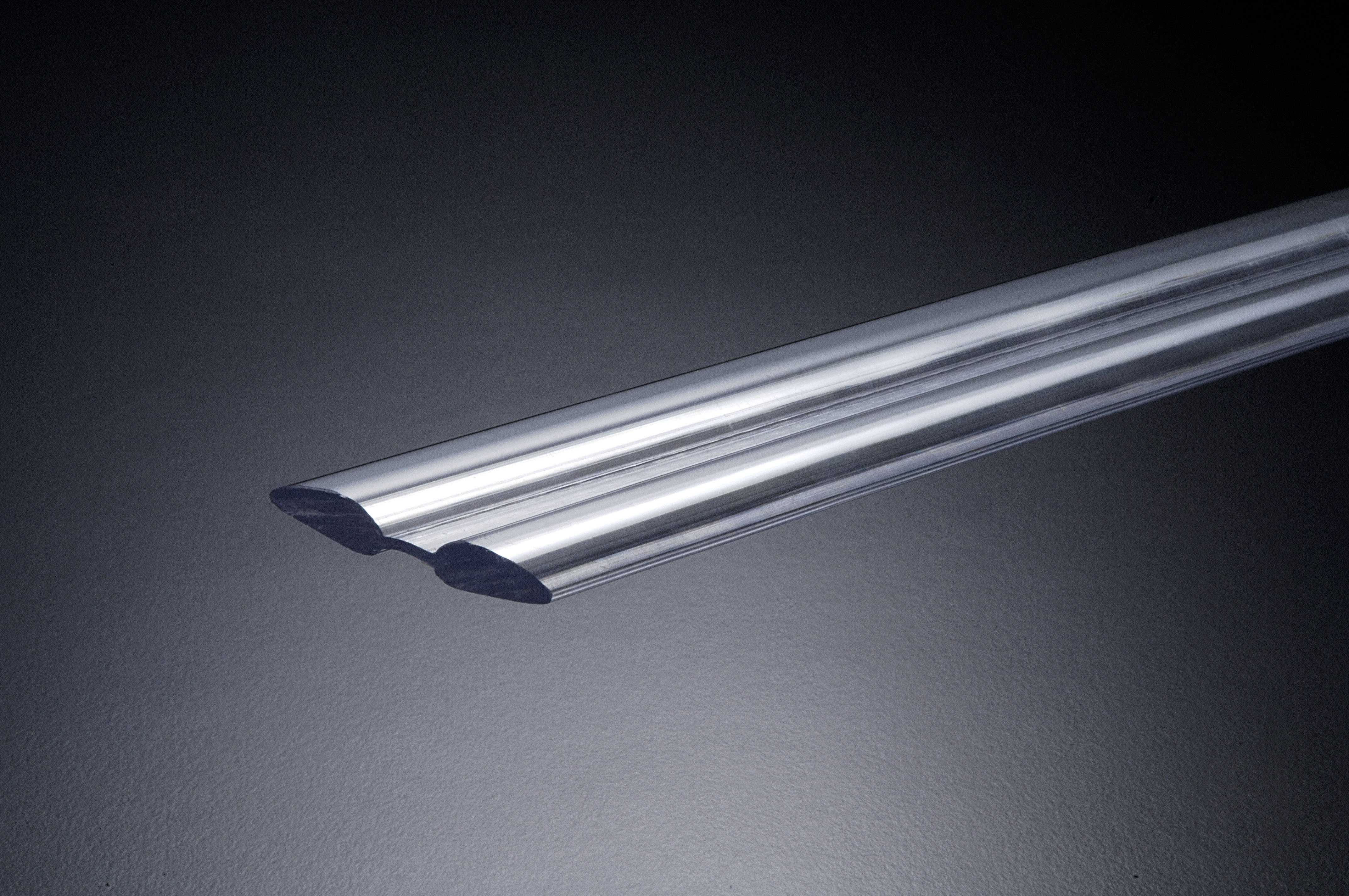

Ease of Processing: Acrylic is fairly easy to cut, shape, and process. This material can be produced in various forms, including sheets, tubes, profiles, etc., and can meet the needs of

different shapes and sizes.

Chemical resistance: Acrylic is highly resistant to many chemicals and is not easily corroded by acids and alkalis. Therefore, it is widely used in laboratories, medical equipment, and chemical

industries.

Thermoformability: Acrylic can be thermoformed under certain heating conditions, so manufacturers can make products of various shapes according to needs.

Colorful: Acrylic can be dyed into various colors and has high gloss, which makes it widely used in art, decoration and other fields.

Impact resistance: Acrylic is more tough than glass and has better resistance to impact, reducing the risk of breakage.

Overall, acrylic is a versatile material with diverse applications, ranging from art to industrial and commercial uses.

Further Reading:PMMA V.S. GLASS

Further Reading:PMMA V.S. GLASS

Related Applications

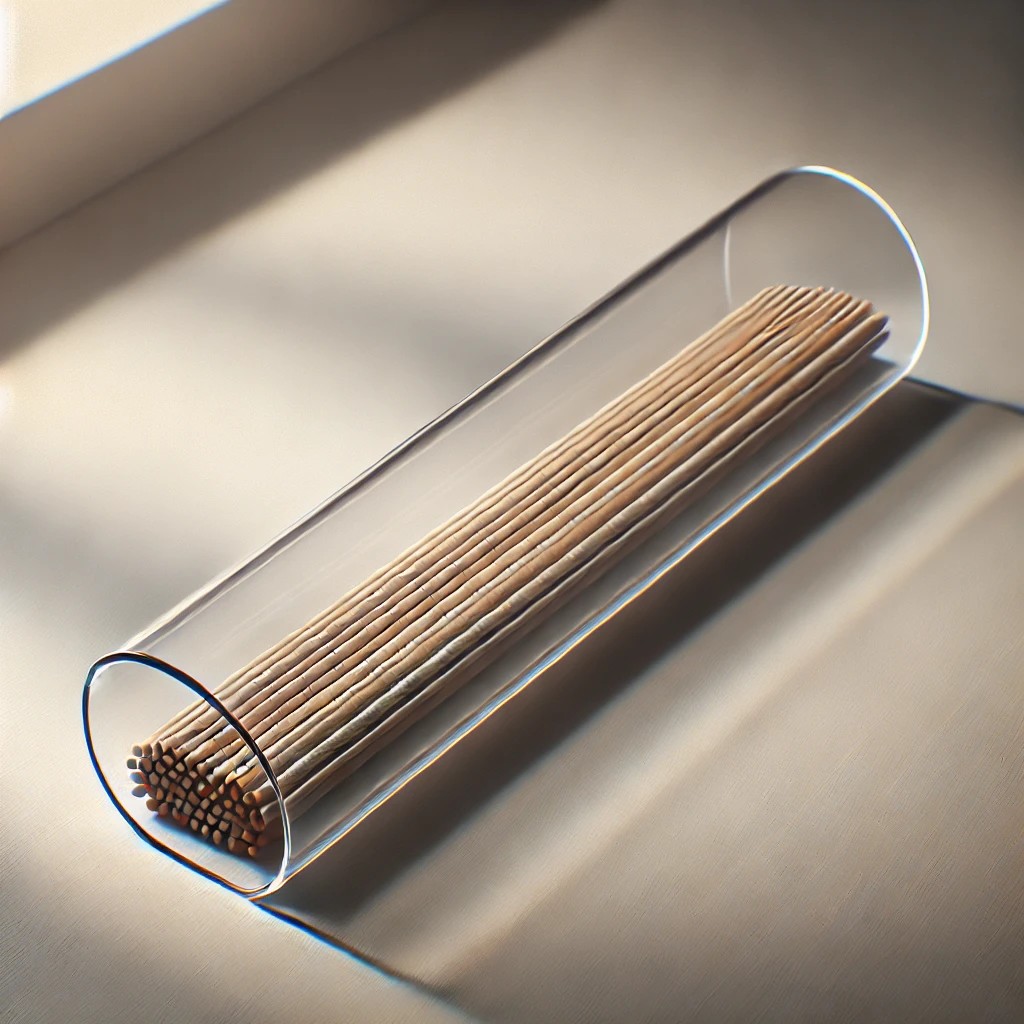

Storage Application

Acrylic material has many applications in storage. Its transparency and modern feel make it a popular storage option, allowing you to clearly see the contents of the box, making it easy to quickly find what you need, such as fish Standard storage tube, incense tube, drill bit packaging tube...etc.

Kaleidoscope Application

Take the kaleidoscope, for example, which often provides children and adults with a wonderful visual experience, allowing people to enjoy the changes in colors and patterns. In addition, it can also demonstrate the characteristics of light and teach students about the principles of light refraction and reflection.

.jpg)

Train Model Display

Acrylic display boxes can protect long model souvenirs while providing a stylish, modern and safe display platform for your collection, and can also add a unique visual effect and sense of value.

Teaching Aid Application

Take hourglasses, for example, which offer a stylish and modern way to tell time. These hourglasses often feature clear acrylic shells, making the passage of time a visual pleasure.

Exhibition Space Partition esign

Take advantage of the transparent properties and changing colors of acrylic tube materials to create unique and memorable displays. It is suitable for various types of exhibitions, exhibitions, events, showrooms and other places to divide the display space and display products or services.

Furniture Applications

Acrylic sticks can also serve many creative and practical purposes. Due to the transparency and sturdiness of acrylic rods, it can bring a unique visual effect and modern feel in furniture design. In addition, combining acrylic rods with other materials, such as metal, wood, etc., can also create more rich and diverse design effects. Whether it’s modern, minimalist or otherwise, acrylic rods make a great addition to furniture designs.