Acrylic Cut? Bend? Glued? Drilling?

Q: How to cut acrylic ?

The cutting of acrylic pipes and rods is generally performed with a sawing table, but it should be noted that the cutting of large pipes needs to be rotated to avoid breaking the pipes.

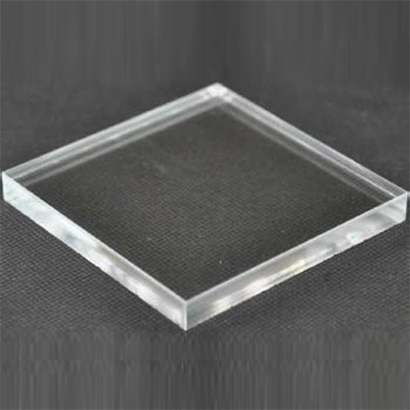

In addition, when cutting acrylic sheets under 5mm, in addition to laser (laser) cutting and sawing,you can also use an "acrylic knife" to repeatedly cut the grooves to half the thickness of the board,and then follow the The acrylic

sheet is broken off by the side of the table. If you need to cut thick acrylic sheets, it is recommended to seek a professional acrylic processing factory.

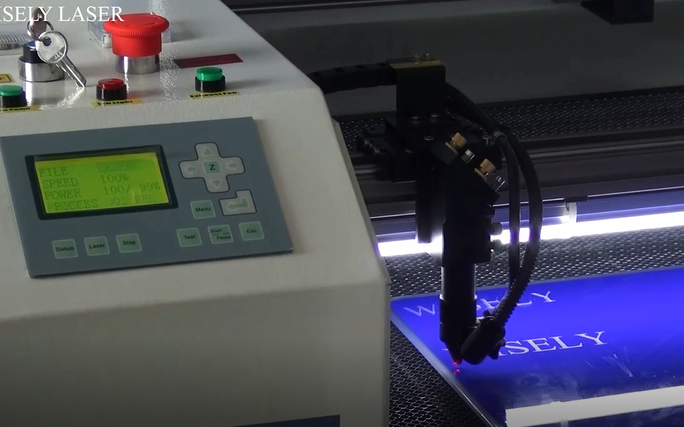

Introduction to Laser Cutting

◆ High efficiency, high accuracy, controlled by computer, automatically cutting and carving out the designed pattern.

◆ The cut surface is smooth, comparable to flame polishing, and less stressed.

◆ The cutting speed, laser power and board thickness need to be considered.

◆ Exhaust equipment is required.

In addition, in fact, acrylic can be easily cut by a tungsten steel blade. However, the frictional heat generated during cutting may damage the acrylic surface.

Q: How acrylic is glued?

The bonding methods of acrylic are divided into chloroform, polymerization, and UV bonding. The most commonly used is chloroform, which is stored in a brown glass bottle.

The principle is to dissolve the acrylic for bonding. The injection point of the cylinder is between the two plates, and it is bonded by means of penetration. If chloroform is not easy to buy, quick-drying three-second glue can also be used.

Step 1: Make sure the surfaces to be bonded are dry and free of any dust or dirt.

Step 2: Using a solvent suitable for acrylic, evenly coat one surface.

Step 3: Gently press the two surfaces together and wait until the solvent has evaporated.

It should be noted that when performing acrylic bonding, it needs to be carried out in a well-ventilated place, because these adhesives are poisonous. Also, be careful not to get glue or solvents on your hands or skin as they could cause irritation or an allergic reaction.

Q: How to Bend Acrylic?

It is common to bend acrylic sheets, but acrylic pipe rods can also be bent. The acrylic pipe rods are heated, softened and placed on a jig covered with soft flannel, and can be shaped

after cooling. , the best environment for thermal forming processing is the temperature of 130-150 ℃. If you do not have professional processing equipment, you can refer to our DIY bending video below.

Step 1: Put the bending mold inside the acrylic tube so that it is aligned with where you want to bend it.

Step 2: Use a heat source to heat the area to be bent until it becomes soft and elastic.

Step 3: Quickly bend the acrylic to the desired shape, and press until it cools and solidifies.

It should be noted that when bending the acrylic tube, excessive bending or excessive heating should be avoided to avoid deformation or cracking of the acrylic tube. At the same time, when using heat sources such as heat guns, care should be taken to protect hands and eyes to avoid damage caused by heat sources.

Q: How to drill holes in acrylic?

◆ Choose a drill:Most suitable for drill top angle between 60° and 90°, drill lip clearance angle 12° -15°, drill lip half angle 10° - 20°

◆ Drilling speed:For a 100mm diameter drill bit, 800RPM is recommended. Smaller drills can be slightly faster, larger drills need to be slower.

Attention:

1. When drilling a hole, friction will increase the temperature, resulting in an unsatisfactory hole drilled. The heating rate can be reduced by blowing air or injecting soapy water.

2. Sawdust will hinder cooling; when drilling deep holes, it is necessary to clean the drill bit frequently.

3. Maintain a proper rotation speed; if the rotation speed is too fast, the cutting edge will be uneven, and if the rotation speed is too slow, the drill bit will be sticky.

4. Always pay attention to whether the drill bit is in good condition; for example, whether the drill bit is sharp or bluntly damaged

Note: In addition to paying attention to the above points, the drill bit should also be adjusted according to the situation, so that drilling will be a very simple matter.

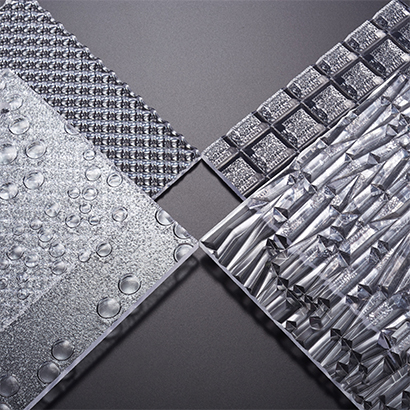

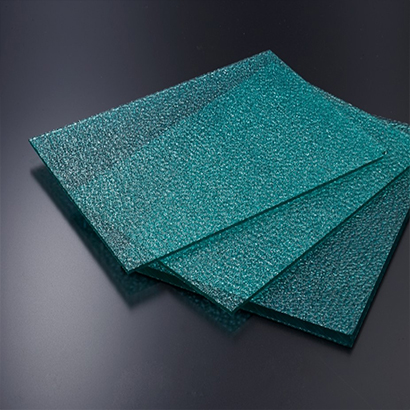

Q: acrylic surface treatment?

Acrylic is an easy-to-process material. You can request a professional acrylic processing factory for dyeing, printing, sandblasting, bronzing, etc., all of which can achieve the effect you want.

In addition, acrylic is fragile and easy to scratch. At this time, surface coating can be applied to increase the durability and strength of acrylic. The coating is transparent and nude, which has little effect

on the original light transmittance of the product.

The following are common types of acrylic finishes:

1. Manual polishing: Use hand tools such as sandpaper or grinding wheels to polish the acrylic surface to make it smooth and even. This method is suitable for the treatment of small areas and rough surfaces.

2. Machine polishing: Use machine equipment, such as grinding machines, polishing machines, etc., to polish the acrylic surface. The effect is more uniform than manual polishing, and it is suitable for large-area and flat surface treatment.

3. Engraving:use laser cutting or mechanical cutting technology to engrave the acrylic surface into different patterns, characters or images. This method is suitable for occasions where special textures or patterns need to be produced.

4. Baking paint: spray a layer of paint or baking paint on the acrylic surface to increase its wear resistance and corrosion resistance. This method can also change the color and appearance of the acrylic.

5. Coating treatment: Add special coatings on the acrylic surface, such as anti-ultraviolet, anti-static, anti-scratch and other functions, to improve its durability and use effect.

It should be noted that when performing acrylic surface treatment, an appropriate method should be selected according to specific needs and process requirements. Moreover, the processing time and temperature should be strictly controlled during the processing to avoid deformation or melting of the acrylic.

Related Applications

-1.jpg)

.jpg)

.jpg)