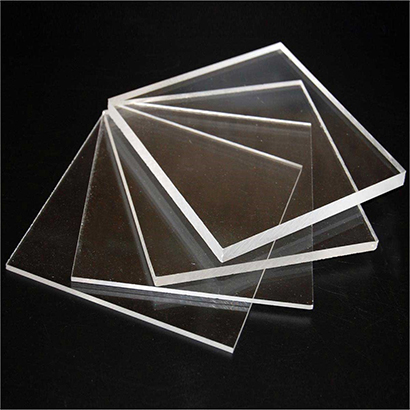

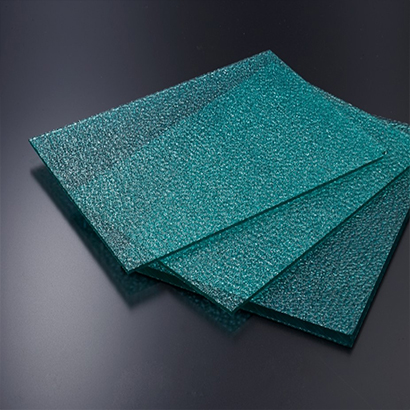

Extruded Acrylic Patterned Sheet

SME acrylic patterned sheet is made by pure 100% PMMA raw materials and made in Taiwan. In the pressing process, the surface is pressed pattern at the same time and the surface is covered with PE non-adhesive protective film to protect it.

Description

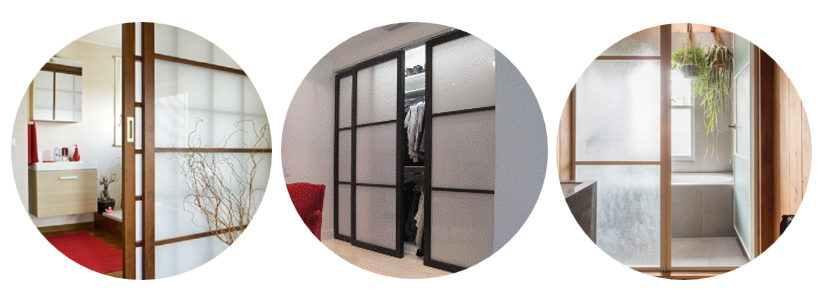

SME acrylic patterned sheet is made by pure 100% PMMA raw materials and made in Taiwan. Produced with the highest standard quality extrusion control process. Suitable for interior decoration, sliding doors, etc.

Extruded Acrylic Patterned Sheet Specifications

• Thickness: 2.0mm~5.0mm

• Width: Max width 1250mm

• Any colors can be produced.

• 3 kinds of standard size:

(1) 915mm*1830mm (3ft*6ft)

(2) 1220mm*1830mm (4ft*6ft)

(3) 1220mm*2440mm (4ft*8ft)

• Cutting: The product can be cut into different sizes according to the requirement of the customers.

• Please click here to see all the patterns and specificaitons of our Extruded Acrylic Patterned Sheet.

to see all the patterns and specificaitons of our Extruded Acrylic Patterned Sheet.

Extruded Acrylic Patterned Sheet Features• High transmittance up to 93%, replace for glass.

• Excellent mechanical resistance.

• Good electricity insulation.

• Waterproof, moisture-proof, stable and durable.

• Green material, non-toxic.

• High impact strength.

• Crack resistance.

• Excellent weather resistance.

• Anti-UV and heat resistance.

Extruded Acrylic Patterned Sheet Applications

• Advertisement: Exhibition, display, digital printing, silk screen printing, engraving materials, sign board, etc.

• Furniture: Office furniture, cabinet, bath cabinet, room segments, ect.

• Finishing Material: Decorative sheet, storage racks, room segment, ect.

• Industrial Application: Thermoforming products.

Related Applications

.jpg)

Layout Application

Place an acrylic mirror plate on the wedding banquet table as the base for the center piece, on which you can place flowers, candlesticks, bottles and other decorations, which will reflect beautifully on the mirror surface.

-1.jpg)

Desktop Applications

Acrylic mirror panels in desktop applications can add a modern and stylish feel to your office space or home environment. Its transparency and modern feel make it a versatile desktop material.

Eaves Board Application

Acrylic panels can be used as eaves panels to provide effective sunshade and rainproof functions. They have strong weather resistance and durability, can resist sunlight, wind, rain and ultraviolet rays, and are not easy to deform, discolor or age.

.jpg)

Wall Sticker Application

Acrylic mirror panels are cut into various shapes and sizes and adhered to the wall to create a mirrored wall, which can make the space brighter, more open, and add visual depth.

Ceiling Design

Install acrylic mirror panels on the ceiling to coordinate with lighting equipment. When the light shines on the acrylic mirror panel, it will create a gorgeous reflection effect on the ceiling, enhancing the fashion and brightness of the space.

Counter Display Application

Acrylic display stands are a common tool for displaying and displaying products. They are widely used in commercial environments. They can display various commodities such as commodities, product samples, stationery, jewelry, cosmetics, mobile phones and electronic products to enhance the value of products.

Customized Acrylic Processing Service

- Cutting: Cutting according to the size required by customers, the precision tolerance can reach ±0.5mm

- Polishing: Treat the acrylic surface with a diamond polishing machine to make it smooth and translucent.

- Drilling: Drilling according to customer's requirements, and it is matched with customer's sample kit.

- Bending: Bending according to customer's requirements, heating the acrylic tube, and then bending with jigs.

- Chamfering: The edge of the acrylic pipe is chamfered to reduce sharp edges.

- Printing: Print patterns, words or images onto the acrylic surface to achieve personalized decorative effects.

- Laser cutting: Using high-power laser beams for precise cutting can achieve diverse cutting needs.

- Assembly: process and assemble with the accessories required by customers to complete one continuous line service.

Not all acrylic specifications are available for the above

services, please inform us of your needs first, SMEACRYLIC will have a professional team to

evaluate for you.

About SMEACRYLIC®

- SMEACRYLIC® is a Taiwan based manufacturer which was founded in year 1980, a Professional Manufacturer in Extrusion Technology.

- We specializes in extruding various kinds of plastic Profiles, Tubes, Rods and Sheets which be used in displays, decorations, lighting, illuminated advertising, architectures and a lot more applications.

- Approximately 90% of our products are exported to over 40 countries worldwide including numerous well-known brands. Over the years, we have expanded to become the market leader in extrusion field in Asia.

QUALITY WE CARE

We insist on using 100% virgin materials.

We insist on using international branded raw materials (Sumipex, Mitsubishi, Evonik)

We insist on keeping sample records of raw materials, all raw materials are traceable.

Technical Service

SME is a customer driven company. Only

satisfied customer will ensure our

continued success. Buying goods from SME you can have a

comprehensive consulting service

package.

The following are some of the systems that we

implemented to provide our

customers with the excellent support and service.

- We developed on line catalogue for our customers.

- Stock system always offers efficient prompt delivery.

- Samples available for most of our products.

- Our home-made moulds offer fast and precision work to ensure customers' satisfaction.

- Efficient ISO-9001 managing system ensures quality stability.

Manufacturing Process

Raw material import

100% virgin material

Raw material inspection

Test raw material melt index

Pre-drying

Raw material drying, remove moisture

Extrusion

Shapes produced through different dies

Cooling

Cooling and shaping

Puller

Control extrusion speed

Cut to size

Cut according to the required length

Projection measure

Accurately measure via magnification

QC inspection

4 steps inspection applies during

extrusion

Packaging

Carton package to enhance product

protection

Warehousing

Instant warehousing, EPR control

Shipment

Well packed for delivery

Inspection Equipment

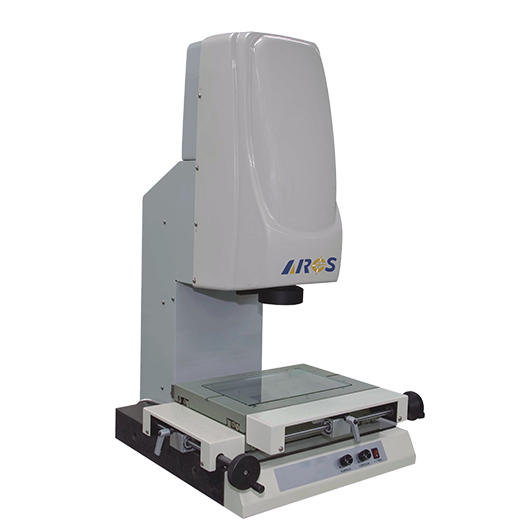

Non-contact Image Measure System

Equipped with a high-resolution and

high-precision color camera to

accurately measure the size through magnification.

Illumination Meter

Accurately measure illuminance, color

temperature, CRI, spectrogram, and

light measurement related data.

Calipers

We use Mitutoyo LCD vernier calipers from

Japan to ensure that the size

and tolerance requirements.

Melt Flow Indexer

To detect the Melt Index of raw materials

to ensure the quality and

stability of raw materials.

Moisture Analyzer

To quickly determine the free water

content of chemical raw material

samples.

Temperature & Humidity Test Chamber

Simulate the environment of high

temperature and high humidity to test the

material change and strength attenuation of our

products.

Production Equipment

Profile Extrusion Machines : 22 lines

7lines

Acrylic Rods

9lines

Acrylic Tubes

6lines

Other Profiles

3,500tons / yr

Production Capacity

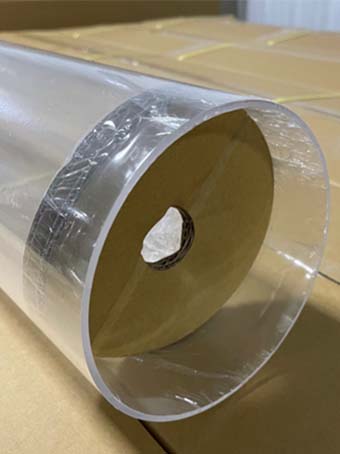

Perfect Packaging

SMEACRYLIC® packaging advantages

- Exclusive shrink film packaging slows down the water absorption of acrylic

- Giving you a good cutting experience

- Effectively avoid scratches on acrylic tube surface during cutting

- Small tubes are bundled to increase the strength and are not easy to break

- Bubble Wrap protects the tubes druing transportation

- Carton protection, convenient for warehouse management

- Square package, maximizing the storage capacity of the warehouse

ISO-9001 : 2015 CERTIFIED

International Exhibition

Related FAQ

Acrylic cleaning and maintenance

Q: How to clean acrylic? Can it be wiped with alcohol? When cleaning acrylic, you need to use a soft cloth dampened with water to wipe, do not use a vegetable cloth or coarse cloth to avoid scratching the acrylic. Acrylic can be wiped with alcohol, but

it is recommended to spray it on a soft cloth before wiping. Do not use high-concentration alcohol to avoid fog or cracks on the acrylic. Q: What to do if the acrylic has small scratches? If the acrylic has slight scratches, it can be treated with "US NOVUS".

It is a remover, cleaning agent, and maintenance agent. It can wipe off small scratches and make the acrylic back to transparent and bright, but Cannot be used on optical lenses. If the scratches are deep, it is recommended to use a cloth wheel for polishing.

Q: Does acrylic turn yellow? Acrylic has good weather resistance and will not yellow when exposed to UV light for a long time. However, if the plastic material is not 100% new, some recycled materials are added, which will cause the acrylic to yellow. It is

possible that if it has yellowed, it means that it has deteriorated and cannot be handled by cleaning methods. It is recommended to buy it again.

Acrylic Cut? Bend? Glued? Drilling?

Q: How to cut acrylic ? The cutting of acrylic pipes and rods is generally performed with a sawing table, but it should be noted that the cutting of large pipes needs to be rotated to avoid breaking the pipes. In addition, when cutting acrylic sheets under

5mm, in addition to laser (laser) cutting and sawing,you can also use an "acrylic knife" to repeatedly cut the grooves to half the thickness of the board,and then follow the The acrylic sheet is broken off by the side of the table. If you need to cut thick

acrylic sheets, it is recommended to seek a professional acrylic processing factory. Introduction to Laser Cutting ◆ High efficiency, high accuracy, controlled by computer, automatically cutting and carving out the designed pattern. ◆ The cut surface is

smooth, comparable to flame polishing, and less stressed. ◆ The cutting speed, laser power and board thickness need to be considered. ◆ Exhaust equipment is required. In addition, in fact, acrylic can be easily cut by a tungsten steel blade. However, the

frictional heat generated during cutting may damage the acrylic surface. Q: How acrylic is glued? The bonding methods of acrylic are divided into chloroform, polymerization, and UV bonding. The most commonly used is chloroform, which is stored in a brown

glass bottle. The principle is to dissolve the acrylic for bonding. The injection point of the cylinder is between the two plates, and it is bonded by means of penetration. If chloroform is not easy to buy, quick-drying three-second glue can also be used.

Step 1: Make sure the surfaces to be bonded are dry and free of any dust or dirt. Step 2: Using a solvent suitable for acrylic, evenly coat one surface. Step 3: Gently press the two surfaces together and wait until the solvent has evaporated. It should be

noted that when performing acrylic bonding, it needs to be carried out in a well-ventilated place, because these adhesives are poisonous. Also, be careful not to get glue or solvents on your hands or skin as they could cause irritation or an allergic reaction.

Q: How to Bend Acrylic? It is common to bend acrylic sheets, but acrylic pipe rods can also be bent. The acrylic pipe rods are heated, softened and placed on a jig covered with soft flannel, and can be shaped after cooling. , the best environment for thermal

forming processing is the temperature of 130-150 ℃. If you do not have professional processing equipment, you can refer to our DIY bending video below. Step 1: Put the bending mold inside the acrylic tube so that it is aligned with where you want to bend it.

Step 2: Use a heat source to heat the area to be bent until it becomes soft and elastic. Step 3: Quickly bend the acrylic to the desired shape, and press until it cools and solidifies. It should be noted that when bending the acrylic tube, excessive bending

or excessive heating should be avoided to avoid deformation or cracking of the acrylic tube. At the same time, when using heat sources such as heat guns, care should be taken to protect hands and eyes to avoid damage caused by heat sources. Q: How to drill

holes in acrylic? ◆ Choose a drill:Most suitable for drill top angle between 60° and 90°, drill lip clearance angle 12° -15°, drill lip half angle 10° - 20° ◆ Drilling speed:For a 100mm diameter drill bit, 800RPM is recommended. Smaller drills can be slightly

faster, larger drills need to be slower. Attention: 1. When drilling a hole, friction will increase the temperature, resulting in an unsatisfactory hole drilled. The heating rate can be reduced by blowing air or injecting soapy water. 2. Sawdust will hinder

cooling; when drilling deep holes, it is necessary to clean the drill bit frequently. 3. Maintain a proper rotation speed; if the rotation speed is too fast, the cutting edge will be uneven, and if the rotation speed is too slow, the drill bit will be sticky.

4. Always pay attention to whether the drill bit is in good condition; for example, whether the drill bit is sharp or bluntly damaged Note: In addition to paying attention to the above points, the drill bit should also be adjusted according to the situation,

so that drilling will be a very simple matter. Q: acrylic surface treatment? Acrylic is an easy-to-process material. You can request a professional acrylic processing factory for dyeing, printing, sandblasting, bronzing, etc., all of which can achieve the

effect you want. In addition, acrylic is fragile and easy to scratch. At this time, surface coating can be applied to increase the durability and strength of acrylic. The coating is transparent and nude, which has little effect on the original light transmittance

of the product. The following are common types of acrylic finishes: 1. Manual polishing: Use hand tools such as sandpaper or grinding wheels to polish the acrylic surface to make it smooth and even. This method is suitable for the treatment of small areas

and rough surfaces. 2. Machine polishing: Use machine equipment, such as grinding machines, polishing machines, etc., to polish the acrylic surface. The effect is more uniform than manual polishing, and it is suitable for large-area and flat surface treatment.

3. Engraving:use laser cutting or mechanical cutting technology to engrave the acrylic surface into different patterns, characters or images. This method is suitable for occasions where special textures or patterns need to be produced. 4. Baking paint:

spray a layer of paint or baking paint on the acrylic surface to increase its wear resistance and corrosion resistance. This method can also change the color and appearance of the acrylic. 5. Coating treatment: Add special coatings on the acrylic surface,

such as anti-ultraviolet, anti-static, anti-scratch and other functions, to improve its durability and use effect. It should be noted that when performing acrylic surface treatment, an appropriate method should be selected according to specific needs and

process requirements. Moreover, the processing time and temperature should be strictly controlled during the processing to avoid deformation or melting of the acrylic.

Introduction to acrylic supply chain

Q: Introduction to acrylic supply chain Regarding different parts or stages of the Acrylic supply chain or production process, the supply chain is usually divided into upstream, midstream and downstream. Here is an explanation of these terms:

Upstream:Upstream usually refers to the starting part of the supply chain, that is, raw materials and original production processes. For acrylic, include the original chemicals, polymerization process, raw material manufacturers, etc. Asia is an important

region for the production of acrylic raw materials. Many large chemical companies have production facilities in Asia, such as Mitsubishi Chemical Corporation, Formosa Plastics Corporation, Chi Mei Corporation, etc. Midstream:Midstream is the intermediate

portion of the supply chain, typically involving the processing, transformation, and manufacturing of raw materials into semi-finished or finished products. For acrylic, the midstream includes the production of acrylic sheets, tubes, rods or other shapes,

while the molding of acrylic can be divided into injection, extrusion, blow molding, casting... etc., while SMEACRYLIC is The leader in extrusion manufacturing. Downstream:Downstream is the final part of the supply chain, including acrylic processing plants

and dealers, for the processing, sales, and retail of finished products. For acrylic, downstream refers to the use of acrylic materials for cutting, bonding, thermoforming, polishing, laser engraving, inkjet, etc. to customize acrylic products that end users

need, such as signs. , storage boxes, display cabinets, furniture, glass substitutes...etc. This classification helps you understand the roles and functions of different stages in the supply chain, allowing you to quickly find the right supplier for your

needs to meet your acrylic needs. In addition, SMEACRYLIC is a professional extruded acrylic manufacturer with rich extrusion experience. Through different acrylic molds, it can produce a variety of shapes. If you have other acrylic shape requirements , you

are also welcome to provide drawings, we will evaluate and quote for you.

Acrylic Sheet Maintenance and Storage Guidelines

Acrylic Sheet Maintenance and Storage Guidelines To ensure the prolonged use and optimal condition of acrylic sheets, proper maintenance and storage are crucial. Acrylic, being a high-quality transparent plastic material, finds wide applications across

various fields. However, its sensitivity to environmental factors and handling necessitates special care. By adopting correct maintenance and storage practices, we can ensure that acrylic sheets maintain clarity, durability, and superior performance over time.

The following are some recommendations aimed at providing guidelines for the maintenance and storage of acrylic sheets to maximize their potential benefits. Cleaning: When cleaning acrylic, use a mild soap or detergent with lukewarm water and a soft cloth

or sponge. Gently wipe the surface to avoid scratches, avoiding abrasive materials that can reduce clarity. For a streak-free finish, use a microfiber cloth. Avoid Harsh Chemicals: While acrylic sheets are generally corrosion-resistant, their tolerance to

specific chemicals depends on the material's quality and manufacturing process. Acrylic exhibits good resistance to water, acids, and bases. However, exposure to strong, corrosive chemicals such as solvents, acids, or bases may have limitations. It is advisable

to conduct material compatibility tests before using chemicals that may potentially damage acrylic. Scratch Prevention: While acrylic serves as an alternative to glass, it has a lower hardness compared to glass. To maintain the clear surface of acrylic sheets

and prevent scratches, it is essential to be cautious. Typically, acrylic sheets come with a protective film to avoid scratches and the attachment of dirt. It is recommended to perform operations and processing with the protective film in place, ensuring that

the protective paper (film) is only removed at the end. This practice helps preserve the perfection of acrylic sheets. High-Temperature Limit: Acrylic has a high-temperature limit of approximately 70°C. Prolonged exposure to high temperatures can cause acrylic

to soften, leading to loss of shape stability. Avoid exposing acrylic to high temperatures to prevent deformation or damage. For applications requiring high-temperature resistance, consider materials like polycarbonate (PC) or polytetrafluoroethylene (PTFE),

known for better stability at elevated temperatures. Storage: Ensure even weight distribution to avoid imbalance and reduce the risk of deformation. Control stacking height carefully to minimize pressure on acrylic sheets. When stored horizontally, use a flat,

level surface to prevent warping over time. When stored vertically, ensure tight attachment of the entire board, maintaining a 10° inclination to prevent sagging. Additionally, keep the height below 30cm. Use appropriate supports and fixing methods for stable

stacking structure, such as brackets or frames, to prevent lateral movement or collapse. Stacking acrylic sheets should strictly avoid placing heavy objects on them, as acrylic is a relatively fragile material susceptible to deformation, scratches, or cracks

under external pressure and weight. Stacking heavy items may lead to excessive pressure on the sheets, increasing the risk of deformation and adversely affecting their appearance and performance. Avoid Direct Sunlight: While acrylic boasts good weather resistance,

it is strongly recommended to avoid exposing acrylic sheets to direct sunlight to ensure their quality and appearance remain undamaged. UV rays and intense light in sunlight can potentially cause acrylic sheets to yellow and lose their gloss. Store acrylic

sheets away from direct sunlight and extreme temperatures to prevent yellowing or degradation, preserving their original color and preventing deterioration. Temperature and Humidity: When considering the use and storage of acrylic sheets, temperature and humidity

are two crucial factors that require special attention. Acrylic sheets are highly sensitive to changes in temperature and humidity. It is essential to maintain a stable and moderate level of temperature and humidity in the storage area. High humidity may result

in condensation on the surface of acrylic sheets, while low humidity can make the material brittle. To achieve and maintain stable humidity levels, the use of dehumidifiers or humidifiers can be considered, depending on specific needs. Regular Inspection: Regularly

inspecting stored acrylic sheets for signs of damage or degradation, following these recommended maintenance and storage guidelines, will help preserve the optical transparency and physical integrity of the acrylic sheets. Overall, through routine and thorough

inspections, potential issues can be identified and addressed early on, ensuring that acrylic sheets maintain their superior appearance and performance over the long term.