Acrylic Extruded Tube VS. Cast Tube

At present, SMEACRYLIC extruded acrylic round tube, which can produce a maximum outer diameter of 250mm, but if you need a larger size, you can consider casting acrylic round tube, the outer diameter can reach 600mm, thickness 10mm, fixed The length is

1.0~1.2M. The manufacturing process is based on liquid MMA raw material, poured into the tube mold, and formed by the centrifugal principle. The dimensional tolerance is large, the process is long, and one piece can be produced. It is suitable for small-scale

production. Better, because the molecular weight is high, it can withstand temperature of about 90 degrees, but there will be fine cloth wheel throw marks on the surface.

PMMA VS. PC

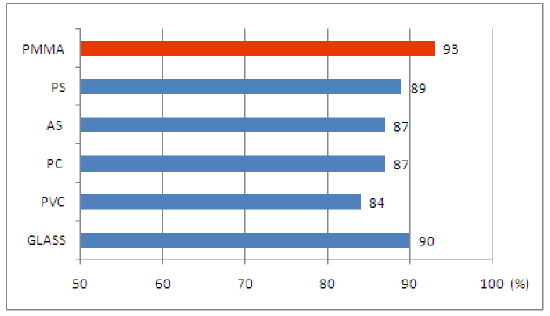

Both have their own advantages and disadvantages, mainly need to consider the way of use and the environment, the following is a comparison table between acrylic and PC for your reference: PMMA acrylic: fragile, light transmittance 92%, processing temperature

70 degrees, not easy to yellow Chemical, cheap PC polycarbonate: impact resistance is 30 times stronger than acrylic, light transmission is 88%, processing temperature is 120 degrees, easy to yellow, and the price is higher

Inspection Equipment

From raw materials to products, SMEACRYLIC has SOP inspection procedures, and its inspection equipment is as follows to ensure that products meet inspection standards....

SMEACRYLIC packaging

Different from the packaging methods of other factories, 99% of the acrylic products produced by SMEACRYLIC are packed in carton boxes. The advantages of this packaging are convenient for warehouse control, transparency of specifications and quantities,

proper protection of products, and avoidance of bumps and damages....

Acrylic Cut? Bend? Glued? Drilling?

The cutting of acrylic pipes and rods is generally performed with a sawing table, but it should be noted that the cutting of large pipes needs to be rotated to avoid breaking the pipes. In addition, when cutting acrylic sheets under 5mm, in addition to

laser (laser) cutting and sawing, you can also use an "acrylic knife" to repeatedly cut the grooves to half the thickness of the board, and then follow the The acrylic sheet is broken off by the side of the table. If you need to cut thick acrylic sheets, it

is recommended to seek a professional acrylic processing factory.