What is Acrylic (PMMA) ?

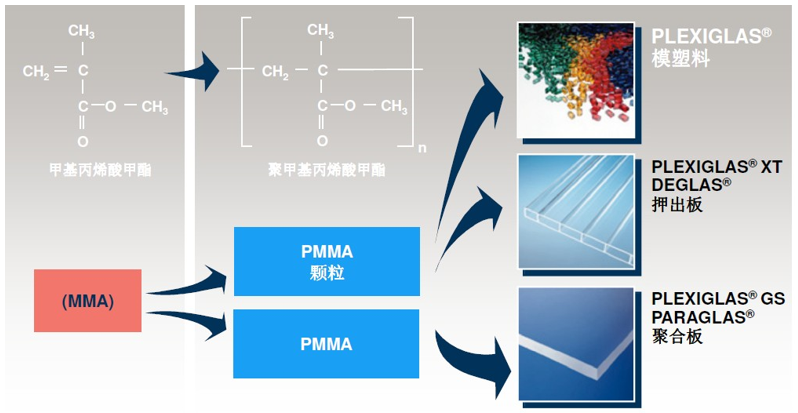

Acrylic is called "polymethyl methacrylate" Poly (methyl methacrylate), referred to as PMMA, also known as plexiglass. It has the reputation of "plastic crystal" and is often used as a substitute for glass. 92% light transmittance, good weather resistance,

easy to machine, can be adhered with chloroform, and suitable for various painting and printing (suitable for acrylic materials).

Acrylic Material properties and benefits?

The water absorption rate of acrylic is 0.3%. If the acrylic material absorbs too much water, it is prone to foaming during thermoforming, and it is also prone to cracking and appearance deformation during printing. If it is stored in a humid environment,

it will affect the expansion and contraction of the product. If you are very demanding on dimensional tolerances, it is recommended to store it in a dehumidification chamber or vacuum treatment. SMEACRYLIC has nearly 100 pings of dehumidification warehouse

space to store all kinds of plates, which can avoid the damage and deformation of the plates due to the humidity of the environment.

Is acrylic environmentally friendly?

Acrylic itself is non-toxic and can be used in medical supplies, contact lenses, food packaging utensils, etc.

Light Guide Rod introduction

Automtive light guide rod are a kind of decoration with linear lights, which are often installed on cars. This decorative item can bring a unique visual effect to the car, improve its recognition and safety, and can also create a unique atmosphere for

the car interior.

Customized Acrylic ?

SMEACRYLIC is the leader in extrusion manufacturing in Southeast Asia. It has 40 years of extrusion experience. The extrusion process is granular PMMA, which is heated and melted into a molten state. Then, the plastic material is pushed into the mold by

extrusion. , and then set by water cooling. After cooling and setting, it will be cut according to the required length. The extruded acrylic products will produce round tubes (rods) or special-shaped products according to different mold shapes.