Acrylic Extruded Tube VS. Cast Tube

Q: Acrylic Cast Tube

At present, SMEACRYLIC extruded acrylic tube, which can produce a maximum outer diameter of 250mm, but if you need a larger size, you can consider Cast Tube, the outer diameter can reach 600mm, Thickness 10mm, The length is 1.0~1.2M. The manufacturing process is based on liquid MMA raw material, poured into the tube mold, and formed by the centrifugal principle. The dimensional tolerance is large, the process is long, and one piece can be produced. It is suitable for small-scale production. Better, because the molecular weight is high, it can withstand temperature of about 90 degrees, but there will be fine cloth wheel throw marks on the surface.

Q: Comparison table of Extruded Tube and Cast Tubes

At present, SMEACRYLIC extruded acrylic tube, which can produce a maximum outer diameter of 250mm, but if you need a larger size, you can consider Cast Tube, the outer diameter can reach 600mm, Thickness 10mm, The length is 1.0~1.2M. The manufacturing process is based on liquid MMA raw material, poured into the tube mold, and formed by the centrifugal principle. The dimensional tolerance is large, the process is long, and one piece can be produced. It is suitable for small-scale production. Better, because the molecular weight is high, it can withstand temperature of about 90 degrees, but there will be fine cloth wheel throw marks on the surface.

Q: Comparison table of Extruded Tube and Cast Tubes

| Acrylic Cast Tube | Acrylic Extruded Tube | |

| Manufacturing Operation |

Using liquid MMA raw material, pour it into the tube mold, It is formed by centrifugal principle and has large dimensional tolerance. The production process is long, and one can also be produced, which is suitable for small-scale production. There will be slight cloth wheel throw marks on the surface. |

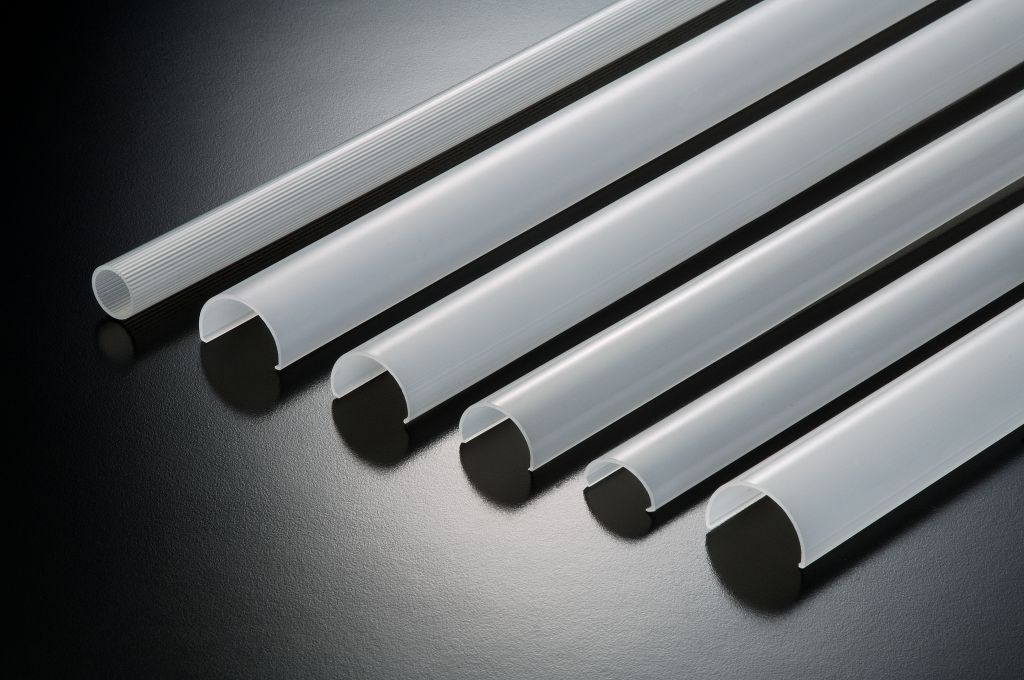

Extruded from granular PMMA, with small dimensional tolerance, Fast production speed, suitable for mass production, It is normal to have small mold marks on the surface. |

| Tolerance | Large | Small |

| Molecular Weight | High (one million) | Low (a hundred thousand) |

| Physical properties | Good (The molecular weight is high, and the temperature resistance is about 90 degrees) | Not Good (the temperature resistance is about 80°) |

| laser cutting | OK | OK |

| Polishing (cloth wheel) | Good (Higher temperature resistance) | Not very Good |

| Drilled (thick) | Good (Good physical properties, high molecular weight) | Need to drill slowly to avoid overheating (more likely to melt) |

| Production restrictions | 1 pcs can also be produced | Production base quantity required |

Related Applications

Indoor Lighting Applications

Acrylic tube rods can also be used in interior furniture design, such as hanging lights, chandeliers, etc. The guidance and refraction of light inside the acrylic tube rods can create a unique lighting effect, adding modernity and personalization to the indoor space.

.jpg)

Air Delivery System Application

It is a system that uses compressed air to transmit files or objects, which can reduce manual operations and material handling while ensuring the accuracy and timeliness of transmission.

Counter Display Application

Acrylic display stands are a common tool for displaying and displaying products. They are widely used in commercial environments. They can display various commodities such as commodities, product samples, stationery, jewelry, cosmetics, mobile phones and electronic products to enhance the value of products.

Gift Box Application

Acrylic gift boxes are transparent and modern. Transparent acrylic materials can clearly display gifts, increase the visual appeal of gifts, and at the same time enhance the sense of value and quality of gifts.

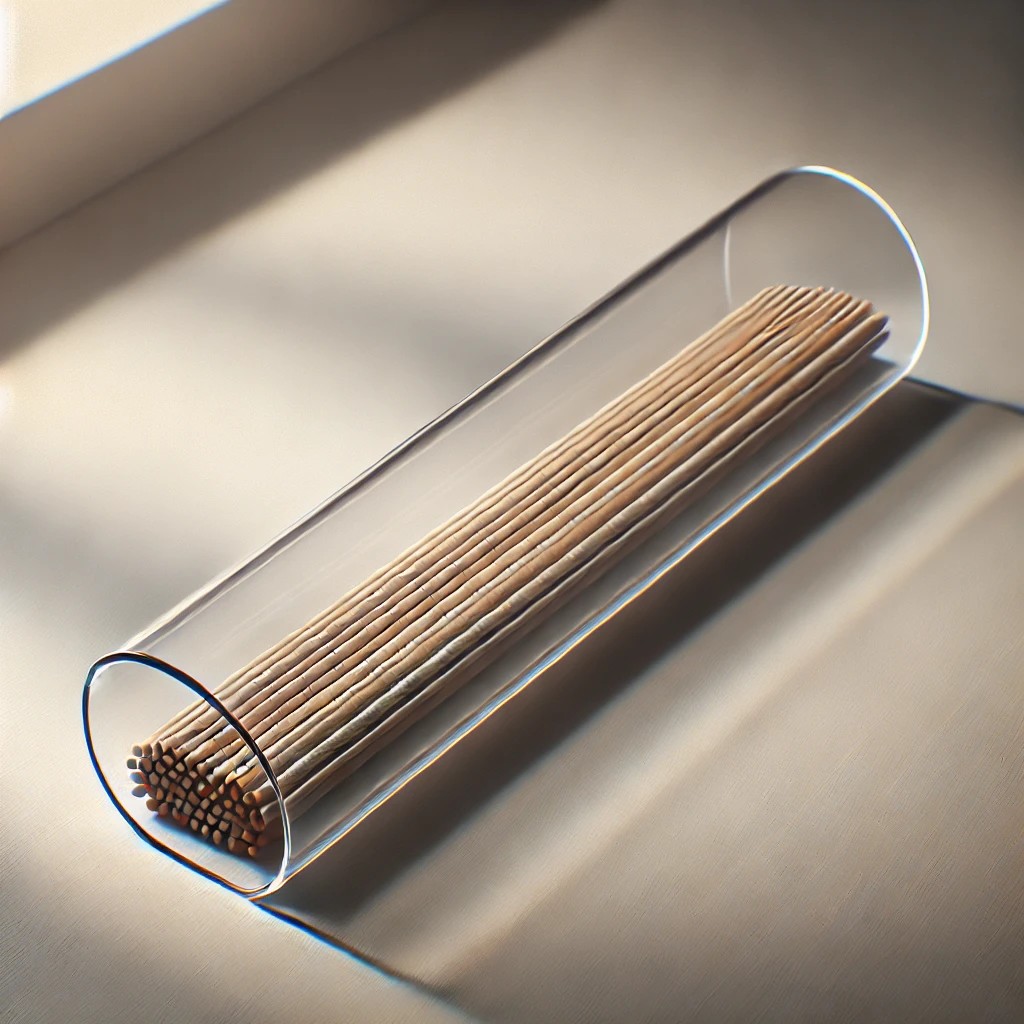

Storage Application

Acrylic material has many applications in storage. Its transparency and modern feel make it a popular storage option, allowing you to clearly see the contents of the box, making it easy to quickly find what you need, such as fish Standard storage tube, incense tube, drill bit packaging tube...etc.

Fence Design Application

This design uses acrylic materials to build fences, replacing traditional brick walls. Its transparent or translucent characteristics allow light to pass through and produce unique visual effects. Although the acrylic fence is transparent, its The materials are generally strong and durable, with good resistance to pressure and impact. This makes it no less safe than traditional fence materials.