Customized Acrylic ?

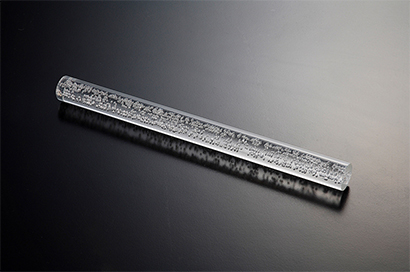

SMEACRYLIC is the leader in extrusion manufacturing in Southeast Asia. It has 40 years of extrusion experience. The extrusion process is granular PMMA, which is heated and melted into a molten state. Then, the plastic material is pushed into the mold by extrusion. , and then set by water cooling. After cooling and setting, it will be cut according to the required length. The extruded acrylic products will produce round tubes (rods) or special-shaped products according to different mold shapes.

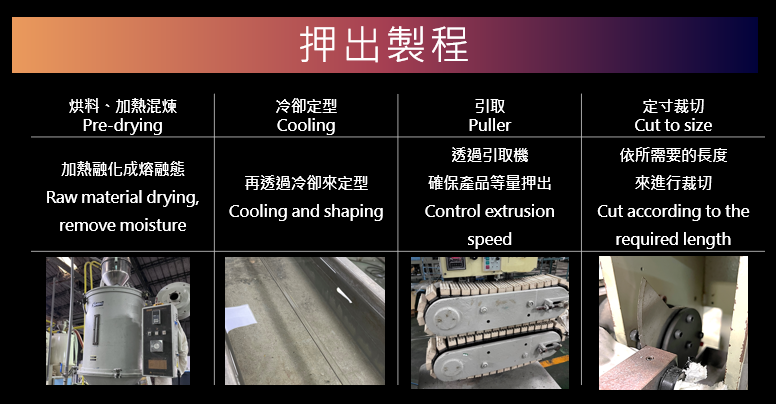

Acrylic extrusion process steps:

1. Material preparation: Melt the acrylic raw material (PMMA particles), usually using a dedicated acrylic extruder. Acrylic is usually supplied in granular form, and different raw materials can be selected according to needs, such as transparency, color, light transmittance, etc.

2. Melting and homogeneous mixing: In the extruder, the acrylic pellets are heated and melted into a fluid state. At the same time, some additives, such as stabilizers, pigments, etc., are usually added to adjust the characteristics and appearance of the product.

3. Extrusion Extrusion: The acrylic melt passes through the screw shaft of the extruder and enters a metal mold with a shape similar to the final product. The shape of the mold can be designed according to the desired product. The acrylic flows through the mold, forming the desired shape.

4. Cooling and curing: Once the acrylic fills the mold, it goes into a cooling zone where it cools and solidifies. This can be achieved by circulating coolant through the mold, or using methods such as cooling fans or water showers to accelerate cooling.

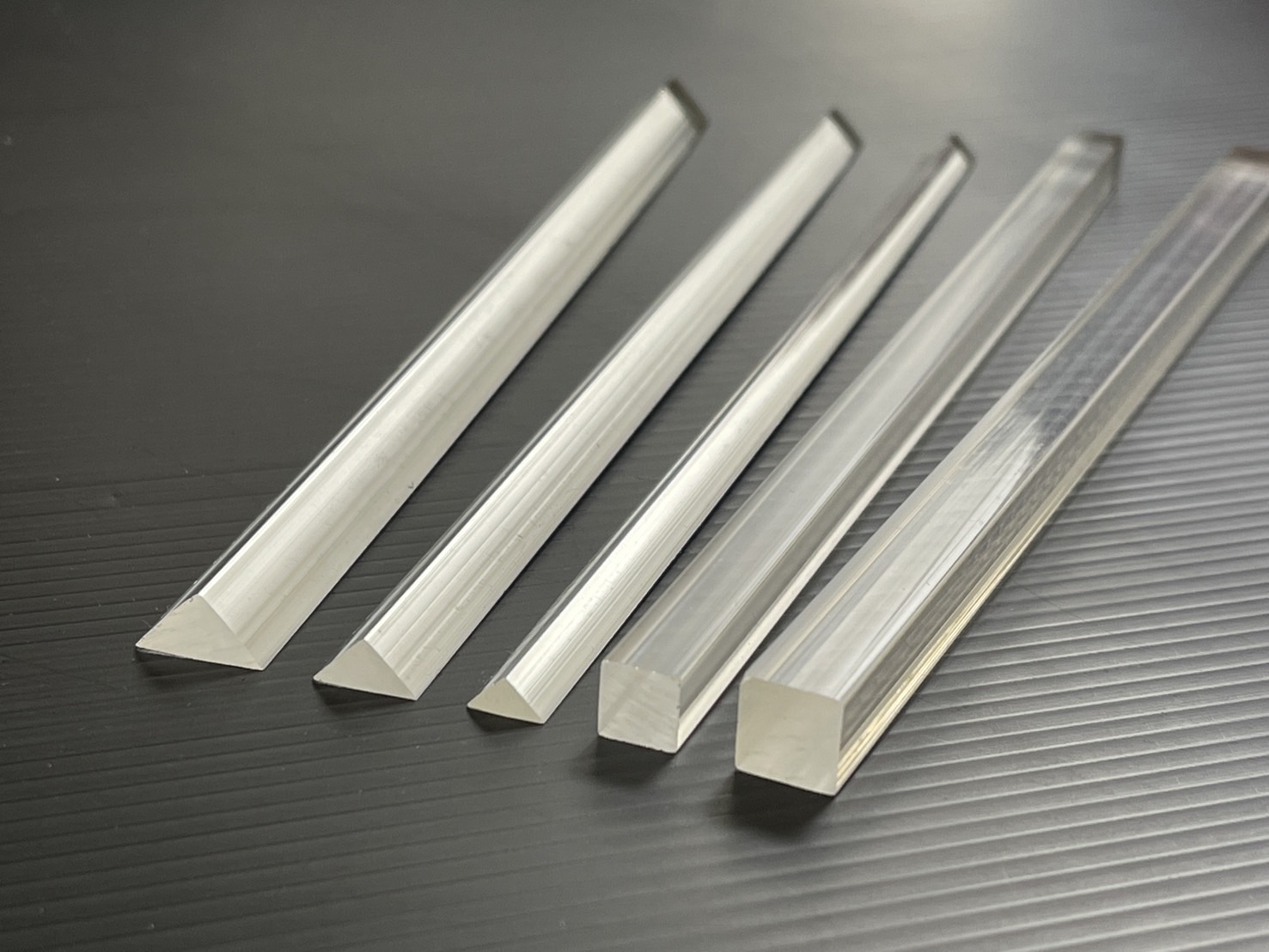

Q: Customized crylic ?

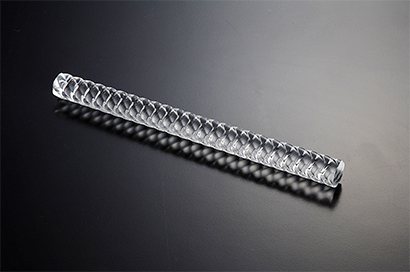

SMEACRYLIC is a professional extruded acrylic manufacturer with rich experience in extrusion. Through different molds, various shapes can be produced. If you have other shapes, please provide drawings, we will evaluate and quote for you.

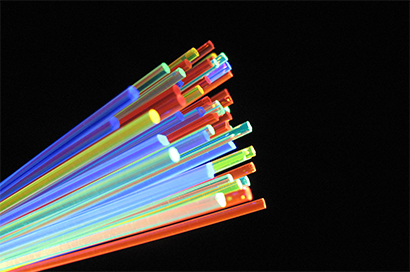

Q: Make colored acrylic?

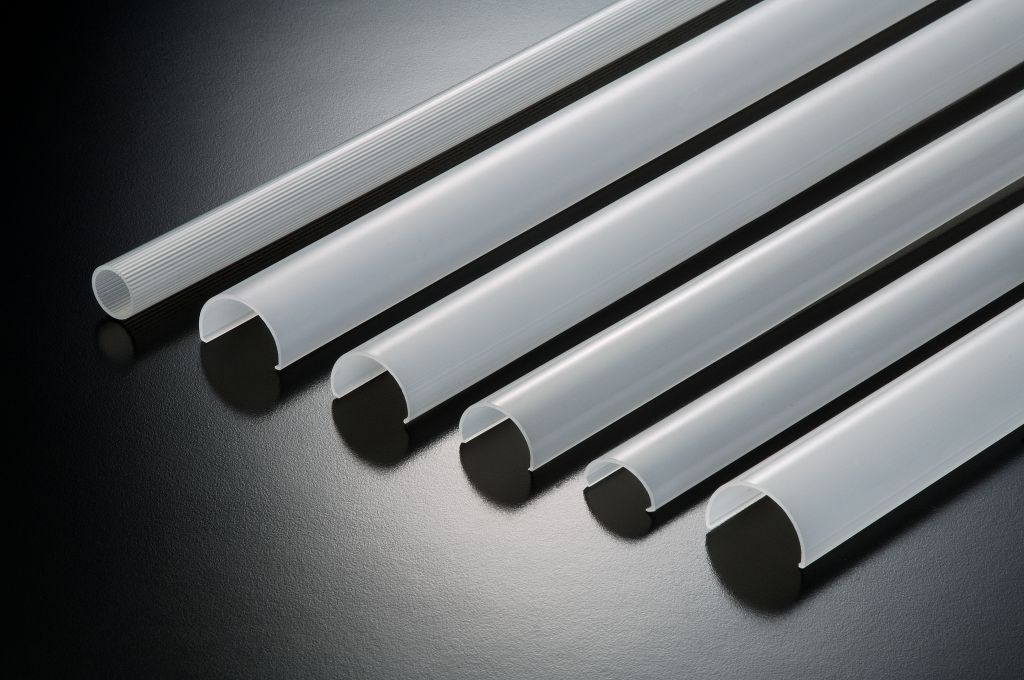

SMEACRYLIC mainly produce acrylic related products such as transparent, milky white, sand ingots, etc. If you need other colors of acrylic tube rods, you can refer to our fluorescent rod products, which are blue, red, yellow and green. Optionally, if it still cannot meet your needs, please provide the color number, we will evaluate and quote for you, or you can also request the acrylic processing factory to complete the needs by processing and dyeing transparent tubes and rods.

Q: What are the dimensions of the extruded acrylic tube?

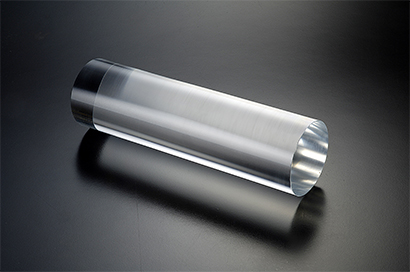

SMEACRYLIC have the most complete size of extruded acrylic tube, the outer diameter of acrylic tube is :Dia.(OD) 5 ~ 250mm, thickness 1/2/3/4/5mm, more than 130 kinds of stock sizes in stock, and other popular shapes and sizes, welcome to inquire. If you need a round tube with a larger outer diameter, you can consider Acrylic Cast Tube, the maximum outer diameter can reach 600mm.

Q: Maximum production length?

Although the extruded material can be extended indefinitely, considering the transportation and storage issues, the longest production length of our company is 6 meters. If you need a longer length, it is recommended to take over and glue it, otherwise there is a risk of breakage.

Related Applications