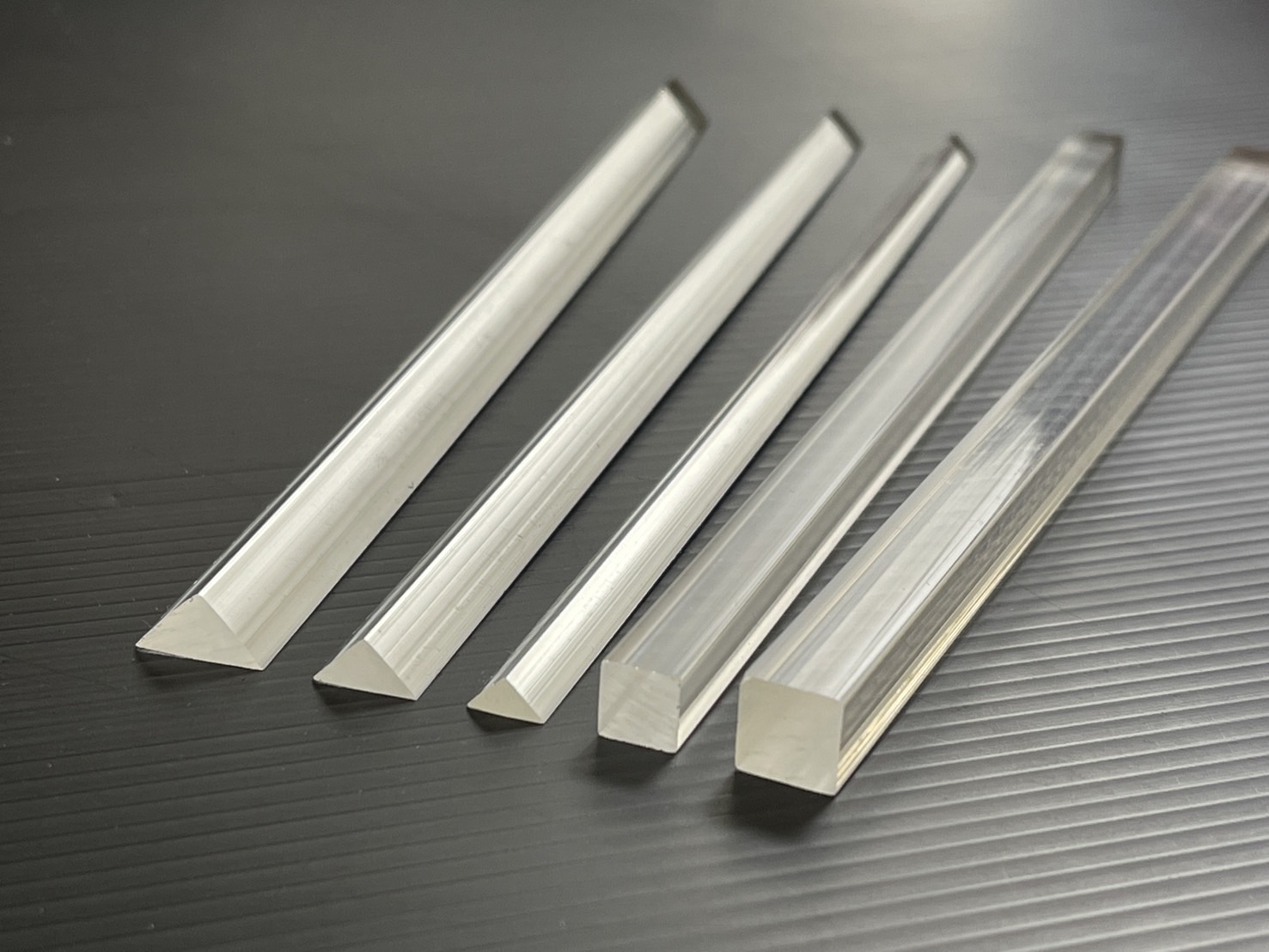

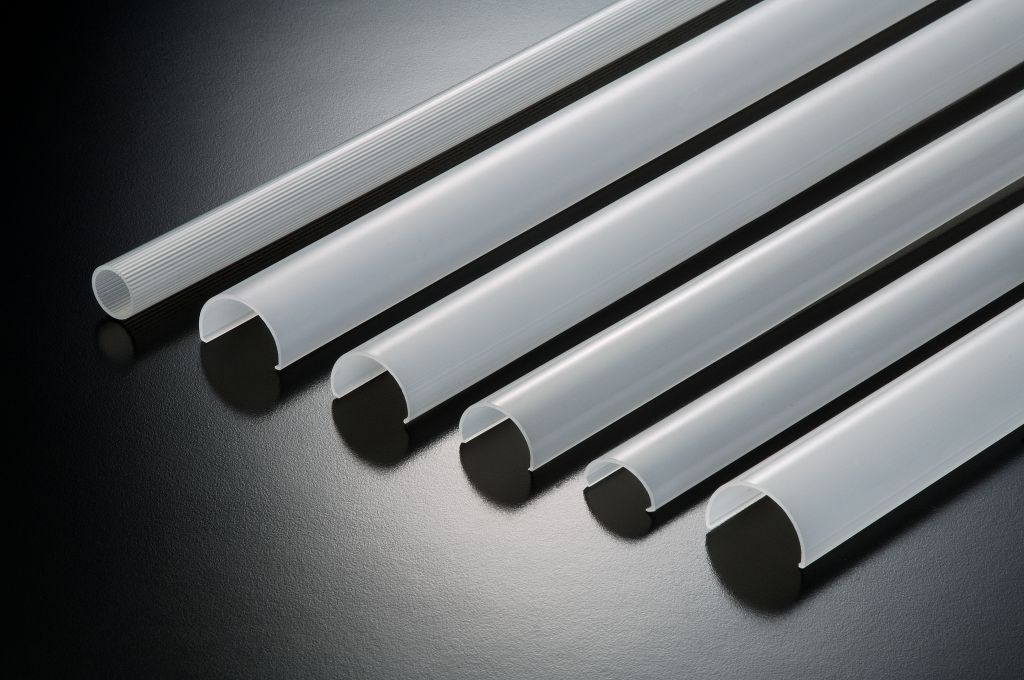

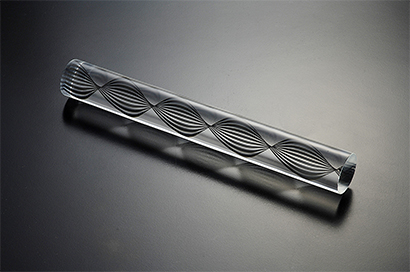

Acrylic supporting rod

Acrylic supporting rod come in triangle and square, specifically designed to stabilize adhesive structures between panels.

Description

• Strengthen structural stability: It can effectively support the connection between panels and improve the stability of the overall structure.

• High transparency: Acrylic material has high transparency and does not affect the visual effect of the design.

• Easy to process and install: Acrylic reinforcement strips can be cut, glued or bent as needed, making them easy to process and install.

• Good weather resistance: It has UV resistance and anti-yellowing properties, suitable for indoor and outdoor use, and will not deteriorate over time.

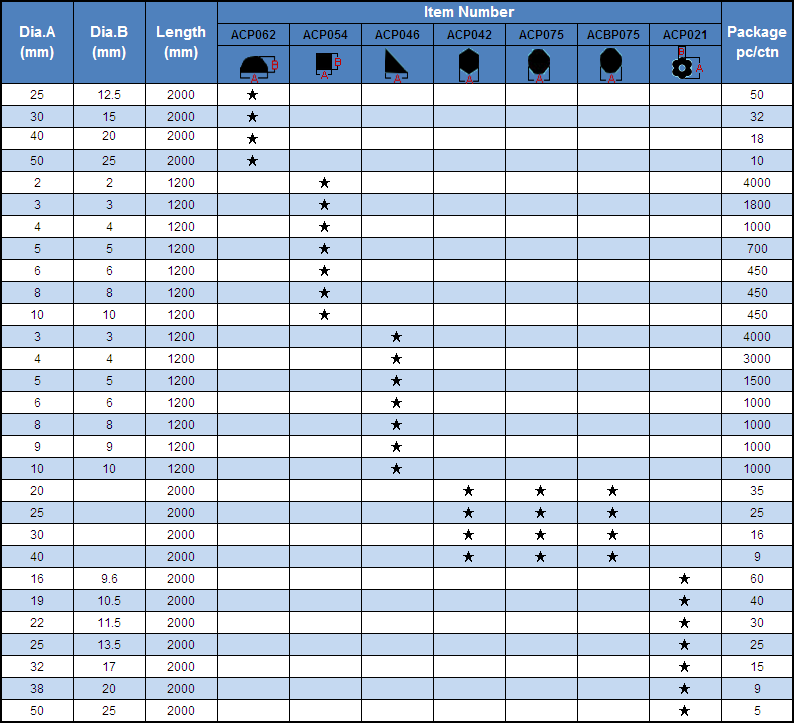

• ACP046 Acrylic Triange Rod, SIZE: 3,4,5,6,8,9,10mm, L:1220mm

• ACP054 Acrylic Square Rod, SIZE: 3,4,5,6,8,10mm, L:1220mm

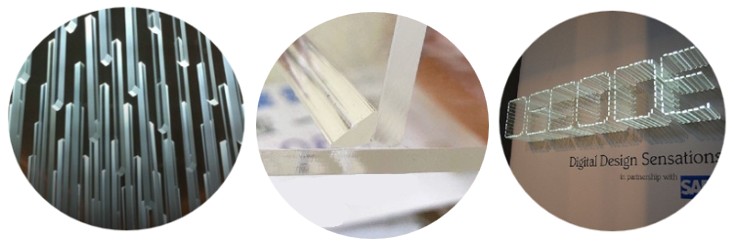

Acrylic Supporting Application

Related Applications

-1.jpg)

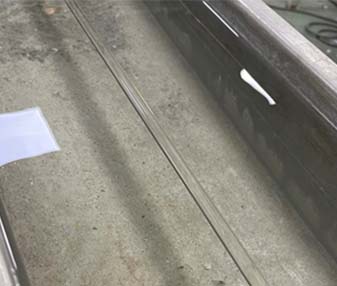

- Cutting: Cutting according to the size required by customers, the precision tolerance can reach ±0.5mm

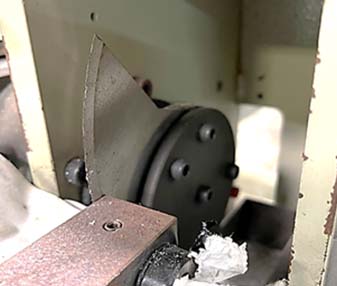

- Polishing: Treat the acrylic surface with a diamond polishing machine to make it smooth and translucent.

- Drilling: Drilling according to customer's requirements, and it is matched with customer's sample kit.

- Bending: Bending according to customer's requirements, heating the acrylic tube, and then bending with jigs.

- Chamfering: The edge of the acrylic pipe is chamfered to reduce sharp edges.

- Printing: Print patterns, words or images onto the acrylic surface to achieve personalized decorative effects.

- Laser cutting: Using high-power laser beams for precise cutting can achieve diverse cutting needs.

- Assembly: process and assemble with the accessories required by customers to complete one continuous line service.

- SMEACRYLIC® is a Taiwan based manufacturer which was founded in year 1980, a Professional Manufacturer in Extrusion Technology.

- We specializes in extruding various kinds of plastic Profiles, Tubes, Rods and Sheets which be used in displays, decorations, lighting, illuminated advertising, architectures and a lot more applications.

- Approximately 90% of our products are exported to over 40 countries worldwide including numerous well-known brands. Over the years, we have expanded to become the market leader in extrusion field in Asia.

We insist on using 100% virgin materials.

We insist on using international branded raw materials (Sumipex, Mitsubishi, Evonik)

We insist on keeping sample records of raw materials, all raw materials are traceable.

- We developed on line catalogue for our customers.

- Stock system always offers efficient prompt delivery.

- Samples available for most of our products.

- Our home-made moulds offer fast and precision work to ensure customers' satisfaction.

- Efficient ISO-9001 managing system ensures quality stability.

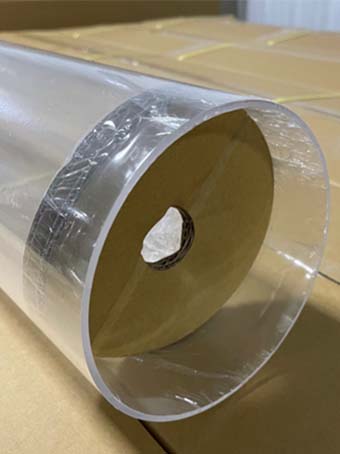

- Exclusive shrink film packaging slows down the water absorption of acrylic

- Giving you a good cutting experience

- Effectively avoid scratches on acrylic tube surface during cutting

- Small tubes are bundled to increase the strength and are not easy to break

- Bubble Wrap protects the tubes druing transportation

- Carton protection, convenient for warehouse management

- Square package, maximizing the storage capacity of the warehouse