PC Lampshades

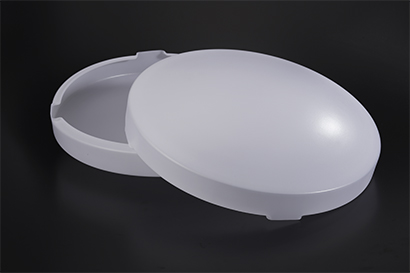

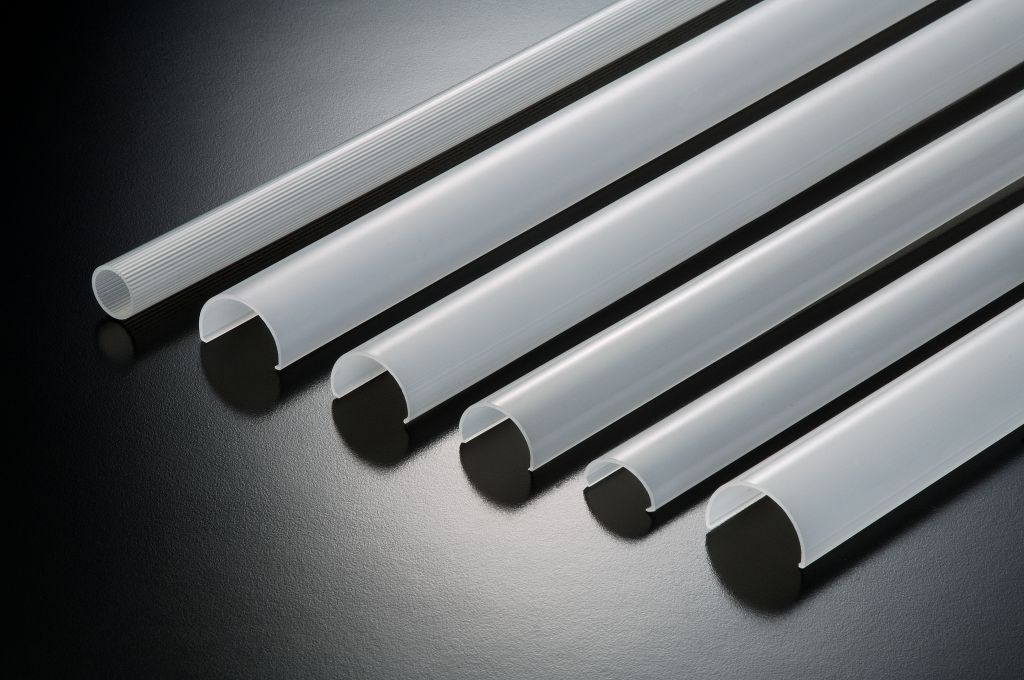

The PC Lampshades produced by SMEACRYLIC feature high transparency and excellent light diffusion. Their durable, shatter-resistant properties provide reliable and safe protection for lighting fixtures. SMEACRYLIC also offers various surface finishes such as clear, frosted, and diffused to meet different design and optical requirements.

Description

PC (polycarbonate) light covers offer excellent impact resistance and heat resistance, making them shatter-resistant and ideal for environments that demand high levels of safety and durability, such as public lighting, industrial fixtures, and outdoor lighting systems. With a high heat tolerance and optional diffusion treatments, PC light covers maintain high light transmittance while providing soft, even illumination—making them an ideal choice that combines structural safety and optical performance.

Types of PC Lampshades

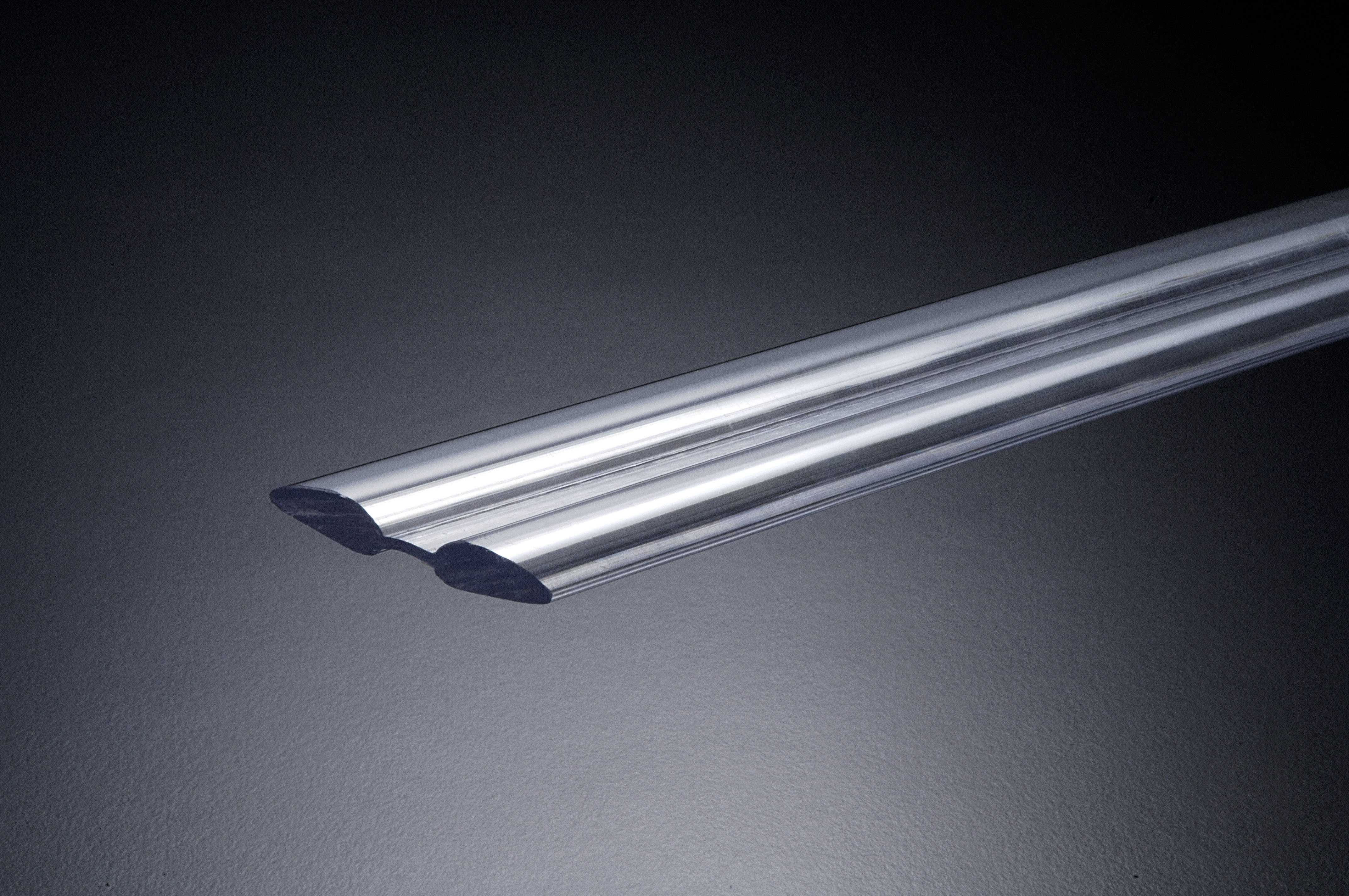

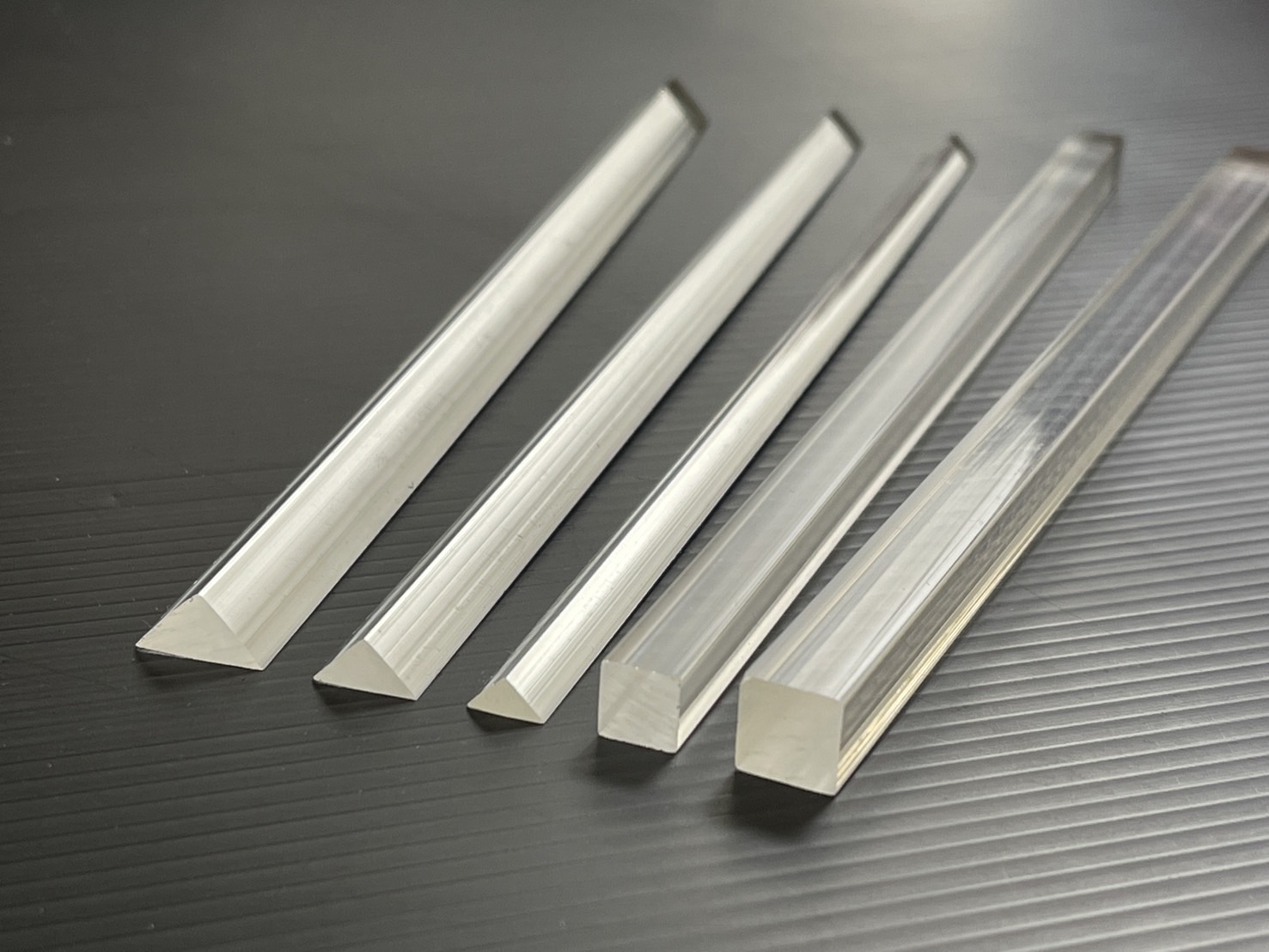

• Round tube covers / semi-circular covers / square tube covers

• Diffused light covers

• Custom extrusion light covers (can be produced based on your design drawing)

Advantages of PC Lampshades

• Good light transmittance

• Excellent heat resistance

• Customizable dimensions and surface finishes

• Impact-resistant and shatterproof

• Great weatherability, suitable for outdoor use

Related Applications

.jpg)

- Cutting: Cutting according to the size required by customers, the precision tolerance can reach ±0.5mm

- Polishing: Treat the acrylic surface with a diamond polishing machine to make it smooth and translucent.

- Drilling: Drilling according to customer's requirements, and it is matched with customer's sample kit.

- Bending: Bending according to customer's requirements, heating the acrylic tube, and then bending with jigs.

- Chamfering: The edge of the acrylic pipe is chamfered to reduce sharp edges.

- Printing: Print patterns, words or images onto the acrylic surface to achieve personalized decorative effects.

- Laser cutting: Using high-power laser beams for precise cutting can achieve diverse cutting needs.

- Assembly: process and assemble with the accessories required by customers to complete one continuous line service.

- SMEACRYLIC® is a Taiwan based manufacturer which was founded in year 1980, a Professional Manufacturer in Extrusion Technology.

- We specializes in extruding various kinds of plastic Profiles, Tubes, Rods and Sheets which be used in displays, decorations, lighting, illuminated advertising, architectures and a lot more applications.

- Approximately 90% of our products are exported to over 40 countries worldwide including numerous well-known brands. Over the years, we have expanded to become the market leader in extrusion field in Asia.

We insist on using 100% virgin materials.

We insist on using international branded raw materials (Sumipex, Mitsubishi, Evonik)

We insist on keeping sample records of raw materials, all raw materials are traceable.

- We developed on line catalogue for our customers.

- Stock system always offers efficient prompt delivery.

- Samples available for most of our products.

- Our home-made moulds offer fast and precision work to ensure customers' satisfaction.

- Efficient ISO-9001 managing system ensures quality stability.

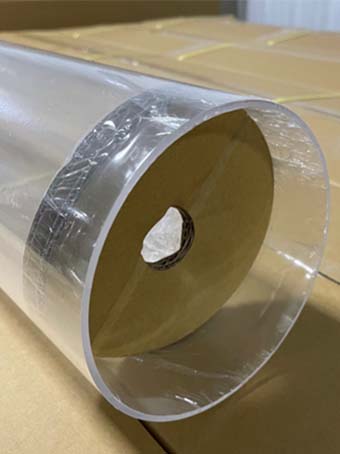

- Exclusive shrink film packaging slows down the water absorption of acrylic

- Giving you a good cutting experience

- Effectively avoid scratches on acrylic tube surface during cutting

- Small tubes are bundled to increase the strength and are not easy to break

- Bubble Wrap protects the tubes druing transportation

- Carton protection, convenient for warehouse management

- Square package, maximizing the storage capacity of the warehouse

.jpg)