Extruded Acrylic Tube

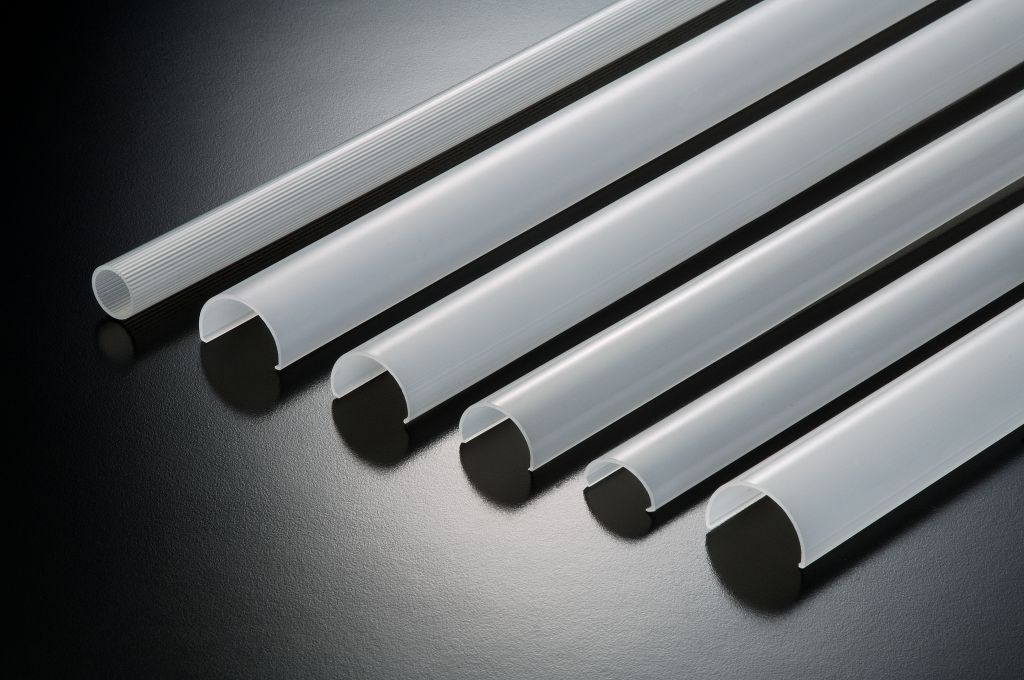

Extruded Acrylic tube :

●Acrylic tube Has very good weather resistance.

●High purity, brightness and transparency.

●Suitable for store fixtures, conveying tube, lighting, and trade show displays.

Description

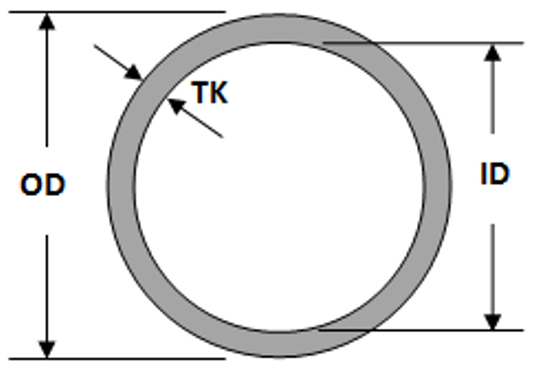

| Outter Dia. (mm) | Inner Dia. (mm) | Thickness (mm) | Outter Dia. Tolerance | Length (mm) |

| 5 | 3 | 1 | ± 0.15 | 2000 |

| 6 | 4 | 1 | ± 0.15 | 2000 |

| 7 | 5 | 1 | ± 0.15 | 2000 |

| 8 | 6 | 1 | ± 0.15 | 2000 |

| 8 | 5 | 1.5 | ± 0.15 | 2000 |

| 10 | 8 | 1 | ± 0.20 | 2000 |

| 10 | 7 | 1.5 | ± 0.20 | 2000 |

| 10 | 6 | 2 | ± 0.20 | 2000 |

| 12 | 10 | 1 | ± 0.20 | 2000 |

| 12 | 8 | 2 | ± 0.20 | 2000 |

| 12 | 6 | 3 | ± 0.20 | 2000 |

| 13 | 9 | 3 | ± 0.20 | 2000 |

| 13 | 7 | 3 | ± 0.20 | 2000 |

| 14 | 10 | 2 | ± 0.20 | 2000 |

| 14 | 8 | 3 | ± 0.20 | 2000 |

| 15 | 13 | 1 | ± 0.20 | 2000 |

| 15 | 11 | 2 | ± 0.20 | 2000 |

| 15 | 9 | 3 | ± 0.20 | 2000 |

| 16 | 12 | 2 | ± 0.30 | 2000 |

| 16 | 10 | 3 | ± 0.30 | 2000 |

| 18 | 14 | 2 | ± 0.30 | 2000 |

| 18 | 12 | 3 | ± 0.30 | 2000 |

| 20 | 18 | 1 | ± 0.30 | 2000 |

| 20 | 16 | 2 | ± 0.30 | 2000 |

| 20 | 14 | 3 | ± 0.30 | 2000 |

| 22 | 18 | 2 | ± 0.30 | 2000 |

| 22 | 16 | 3 | ± 0.30 | 2000 |

| 25 | 21 | 2 | ± 0.40 | 2000 |

| 25 | 19 | 3 | ± 0.40 | 2000 |

| 28 | 24 | 2 | ± 0.40 | 2000 |

| 28 | 22 | 3 | ± 0.40 | 2000 |

| 30 | 26 | 2 | ± 0.40 | 2000 |

| 30 | 24 | 3 | ± 0.40 | 2000 |

| 30 | 22 | 4 | ± 0.40 | 2000 |

| 30 | 20 | 5 | ± 0.40 | 2000 |

| 32 | 28 | 2 | ± 0.40 | 2000 |

| 32 | 26 | 3 | ± 0.40 | 2000 |

| 32 | 24 | 4 | ± 0.40 | 2000 |

| 35 | 31 | 2 | ± 0.40 | 2000 |

| 35 | 29 | 3 | ± 0.40 | 2000 |

| 38 | 34 | 2 | ± 0.40 | 2000 |

| 38 | 32 | 3 | ± 0.40 | 2000 |

| 38 | 30 | 4 | ± 0.40 | 2000 |

| 38 | 38 | 5 | ± 0.40 | 2000 |

| 40 | 36 | 2 | ± 0.40 | 2000 |

| 40 | 34 | 3 | ± 0.40 | 2000 |

| 40 | 32 | 4 | ± 0.40 | 2000 |

| 40 | 30 | 5 | ± 0.40 | 2000 |

| 45 | 41 | 2 | ± 0.40 | 2000 |

| 45 | 39 | 3 | ± 0.40 | 2000 |

| 45 | 37 | 4 | ± 0.40 | 2000 |

| 45 | 35 | 5 | ± 0.40 | 2000 |

| 50 | 46 | 2 | ± 0.40 | 2000 |

| 50 | 44 | 3 | ± 0.40 | 2000 |

| 50 | 42 | 4 | ± 0.40 | 2000 |

| 50 | 40 | 5 | ± 0.40 | 2000 |

| 60 | 56 | 2 | ± 0.40 | 2000 |

| 60 | 54 | 3 | ± 0.40 | 2000 |

| 60 | 52 | 4 | ± 0.40 | 2000 |

| 60 | 50 | 5 | ± 0.40 | 2000 |

| 70 | 66 | 2 | ± 0.60 | 2000 |

| 70 | 64 | 3 | ± 0.60 | 2000 |

| 70 | 62 | 4 | ± 0.60 | 2000 |

| 70 | 60 | 5 | ± 0.60 | 2000 |

| 80 | 76 | 2 | ± 0.60 | 2000 |

| 80 | 74 | 3 | ± 0.60 | 2000 |

| 80 | 72 | 4 | ± 0.60 | 2000 |

| 80 | 70 | 5 | ± 0.60 | 2000 |

| 90 | 86 | 2 | ± 0.60 | 2000 |

| 90 | 84 | 3 | ± 0.60 | 2000 |

| 90 | 82 | 4 | ± 0.60 | 2000 |

| 90 | 80 | 5 | ± 0.60 | 2000 |

| 100 | 96 | 2 | ± 0.80 | 2000 |

| 100 | 94 | 3 | ± 0.80 | 2000 |

| 100 | 92 | 4 | ± 0.80 | 2000 |

| 100 | 90 | 5 | ± 0.80 | 2000 |

| 110 | 104 | 3 | ± 1.00 | 2000 |

| 110 | 102 | 4 | ± 1.00 | 2000 |

| 110 | 100 | 5 | ± 1.00 | 2000 |

| 120 | 114 | 3 | ± 1.00 | 2000 |

| 120 | 112 | 4 | ± 1.00 | 2000 |

| 120 | 110 | 5 | ± 1.00 | 2000 |

| 125 | 119 | 3 | ± 1.00 | 2000 |

| 125 | 117 | 4 | ± 1.00 | 2000 |

| 125 | 115 | 5 | ± 1.00 | 2000 |

| 130 | 124 | 3 | ± 1.20 | 2000 |

| 130 | 122 | 4 | ± 1.20 | 2000 |

| 130 | 120 | 5 | ± 1.20 | 2000 |

| 133 | 127 | 3 | ± 1.20 | 2000 |

| 133 | 125 | 4 | ± 1.20 | 2000 |

| 133 | 123 | 5 | ± 1.20 | 2000 |

| 140 | 134 | 3 | ± 1.20 | 2000 |

| 140 | 132 | 4 | ± 1.20 | 2000 |

| 140 | 130 | 5 | ± 1.20 | 2000 |

| 150 | 144 | 3 | ± 1.20 | 2000 |

| 150 | 142 | 4 | ± 1.20 | 2000 |

| 150 | 140 | 5 | ± 1.20 | 2000 |

| 160 | 154 | 3 | ± 1.50 | 2000 |

| 160 | 152 | 4 | ± 1.50 | 2000 |

| 160 | 150 | 5 | ± 1.50 | 2000 |

| 170 | 164 | 3 | ± 1.50 | 2000 |

| 170 | 162 | 4 | ± 1.50 | 2000 |

| 170 | 160 | 5 | ± 1.50 | 2000 |

| 180 | 174 | 3 | ± 1.80 | 2000 |

| 180 | 172 | 4 | ± 1.80 | 2000 |

| 180 | 170 | 5 | ± 1.80 | 2000 |

| 185 | 179 | 3 | ± 1.85 | 2000 |

| 185 | 177 | 4 | ± 1.85 | 2000 |

| 185 | 175 | 5 | ± 1.85 | 2000 |

| 200 | 194 | 3 | ± 2.00 | 2000 |

| 200 | 192 | 4 | ± 2.00 | 2000 |

| 200 | 190 | 5 | ± 2.00 | 2000 |

| 230 | 222 | 4 | ± 2.30 | 2000 |

| 230 | 220 | 5 | ± 2.30 | 2000 |

| 250 | 242 | 4 | ± 2.50 | 2000 |

| 250 | 240 | 5 | ± 2.50 | 2000 |

※ Please click here![]() to see the specifications of our Extruded Acrylic Tube.

to see the specifications of our Extruded Acrylic Tube.

※ Customize colors and sizes, please contact us. Extruded Acrylic Tube Price is reasonable.

Extruded Acrylic Tube Features

• Excellent weather resistance

• Excellent light transmission, light transmission rate of up to 92%, with crystal clear characteristics

• Machining is simple and convenient

Extruded Acrylic Tube Attention

• Do not coexist with other organic solvents, let alone expose them to organic solvents.

• Cannot be used at temperatures above 85 degrees Celsius.

Extruded Acrylic Tube Application

• Packaging

• Industrial accessories

• Installation of artwork

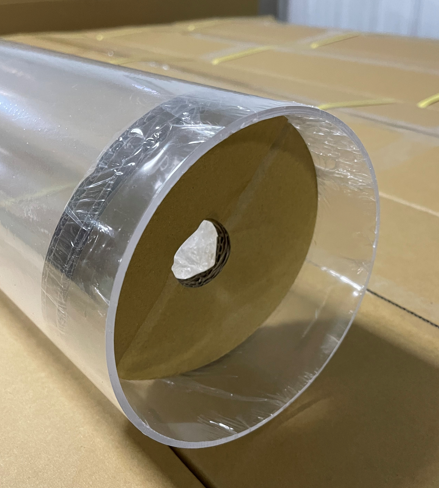

Extruded Acrylic Tube Packaging

Different from the packaging methods of other factories, 99% of the acrylic products produced by SME are packed in cartons. The advantages of this packaging are:

◆ Convenient warehouse management and control, transparent specifications and quantities.

◆ Properly protect the product to avoid bumps and injuries.

◆ Square arrangement storage, maximize the warehouse.

1. For acrylic rods with a diameter of more than 6mm and acrylic tubes of 8~28mm, each piece is put into a PE bag, which can reduce the risk of friction and scratches on the acrylic rod and strengthen the protection of each acrylic rod/tube.

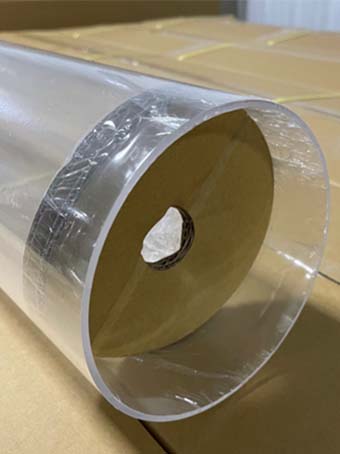

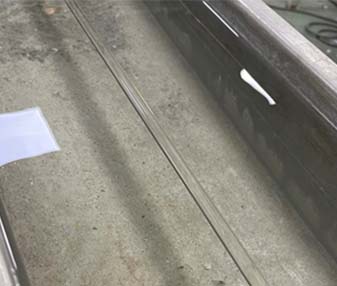

2. The round tube over 30mm is packed with shrink film, and the large tube is then inserted into a round fixed piece to avoid deformation by external force. In addition to slowing down the water absorption of acrylic, it can also reduce the scraping of acrylic fragments during processing and cutting. The risk of injury is not affected by the visual gap between the PE bag and the tube.

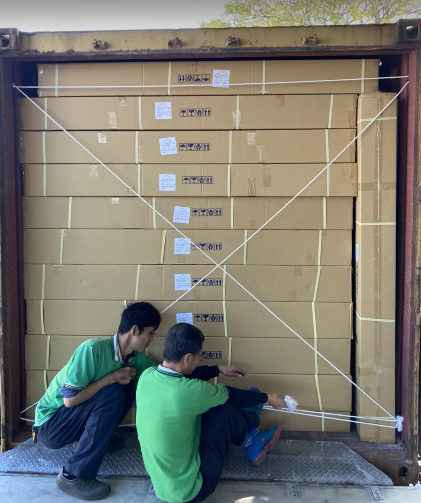

Always pallet packaging by CFS

In order to ensure that the bulk cargo can be safely delivered to the customer, when the bulk cargo is shipped, it must be packaged on pallets to avoid product damage caused by bulk cargo handling. Secured with iron straps.

Remarks: Air freight may not necessarily be shipped on pallets due to consideration of customer shipping costs.

FCL shipment by sea

For customers who leave the whole container, after completing the loading, be sure to pull the rope to protect the goods, and record the photos of the empty container, seal, before and after sealing, so as to ensure the rights and interests of customers.

Related Applications

-1.jpg)

.jpg)

.jpg)

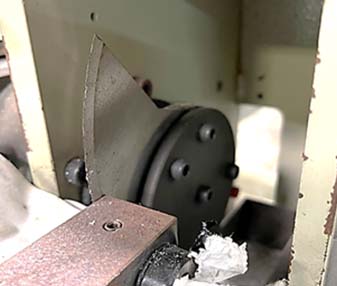

- Cutting: Cutting according to the size required by customers, the precision tolerance can reach ±0.5mm

- Polishing: Treat the acrylic surface with a diamond polishing machine to make it smooth and translucent.

- Drilling: Drilling according to customer's requirements, and it is matched with customer's sample kit.

- Bending: Bending according to customer's requirements, heating the acrylic tube, and then bending with jigs.

- Chamfering: The edge of the acrylic pipe is chamfered to reduce sharp edges.

- Printing: Print patterns, words or images onto the acrylic surface to achieve personalized decorative effects.

- Laser cutting: Using high-power laser beams for precise cutting can achieve diverse cutting needs.

- Assembly: process and assemble with the accessories required by customers to complete one continuous line service.

- SMEACRYLIC® is a Taiwan based manufacturer which was founded in year 1980, a Professional Manufacturer in Extrusion Technology.

- We specializes in extruding various kinds of plastic Profiles, Tubes, Rods and Sheets which be used in displays, decorations, lighting, illuminated advertising, architectures and a lot more applications.

- Approximately 90% of our products are exported to over 40 countries worldwide including numerous well-known brands. Over the years, we have expanded to become the market leader in extrusion field in Asia.

We insist on using 100% virgin materials.

We insist on using international branded raw materials (Sumipex, Mitsubishi, Evonik)

We insist on keeping sample records of raw materials, all raw materials are traceable.

- We developed on line catalogue for our customers.

- Stock system always offers efficient prompt delivery.

- Samples available for most of our products.

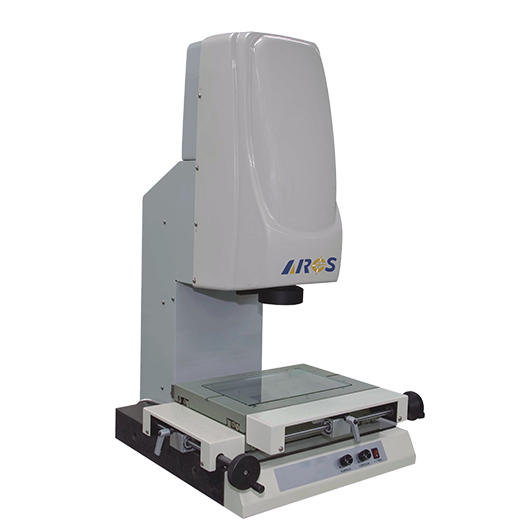

- Our home-made moulds offer fast and precision work to ensure customers' satisfaction.

- Efficient ISO-9001 managing system ensures quality stability.

- Exclusive shrink film packaging slows down the water absorption of acrylic

- Giving you a good cutting experience

- Effectively avoid scratches on acrylic tube surface during cutting

- Small tubes are bundled to increase the strength and are not easy to break

- Bubble Wrap protects the tubes druing transportation

- Carton protection, convenient for warehouse management

- Square package, maximizing the storage capacity of the warehouse

.jpg)