Pet Cage Application

As pet care demands increase, the design of pet cages must consider not only practicality and safety but also aesthetics and comfort. Acrylic tubes, as a modern material, are gradually gaining popularity in the construction of pet cages due to their excellent physical properties and design flexibility. The application of acrylic tubes not only enhances the quality and functionality of pet cages but also provides a safer and more comfortable living environment for pets.

1. Transparent Design Enhances Interaction

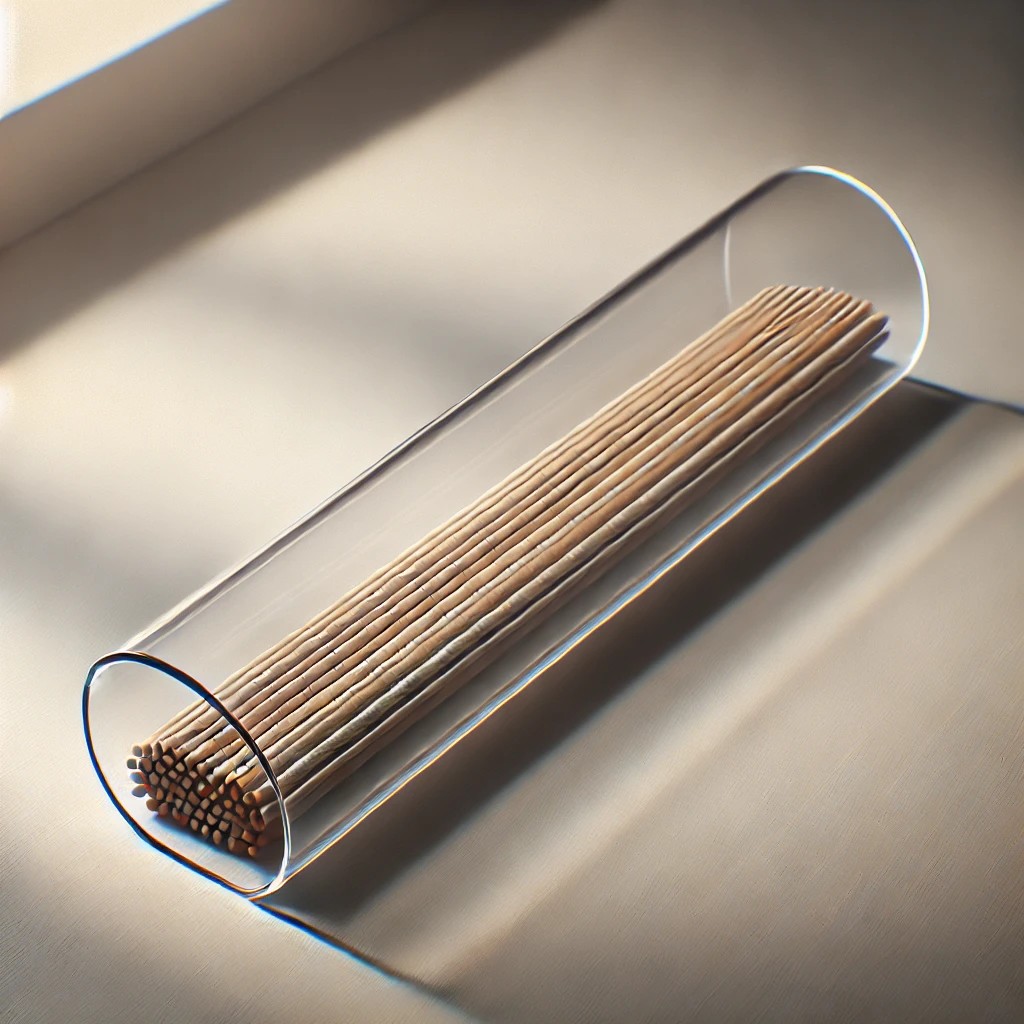

The high transparency of acrylic tubes gives pet cages excellent visual effects, allowing pet owners to clearly observe their pets' behaviors and states, thereby enhancing interaction between them. Additionally, the transparent design creates a more open and secure feeling for pets, reducing any sense of confinement that might come from a closed cage. This transparent structure is particularly suitable for small mammals, reptiles, and birds that require visual stimulation, enabling them to freely explore their surroundings.

Ref.:antfarmsandaquariums.myshopify

2. Durability and Safety

Acrylic tubes provide a sturdy structure for pet cages due to their excellent durability and impact resistance. Compared to traditional metal or plastic materials, acrylic tubes are more resilient and are less likely to break from scratching or biting by pets, or from external forces. This is particularly important for pets with high activity levels, as it effectively prevents injuries or escapes, ensuring their safety.

3. Excellent Ventilation and Space Design

The flexibility of acrylic tubes allows designers to create diverse ventilation systems and internal space structures tailored to different pets' needs. By strategically arranging the layout of the acrylic tubes, optimal air circulation can be achieved inside the pet cage, maintaining good air quality and preventing the accumulation of odors and moisture. Additionally, the flexibility of acrylic tubes can be used to create multi-level or multi-zone cage structures, providing pets with more room to move and explore.

4. Easy to Clean and Maintain

The smooth surface of acrylic tubes is resistant to dirt and bacteria, making cleaning the pet cage simpler and more convenient. Pet owners can easily keep both the inside and outside of the cage clean by simply wiping it down with a damp cloth, which is essential for maintaining the health of their pets. Acrylic material also possesses good waterproof properties, making it suitable for washing and disinfecting, ensuring a hygienic environment within the cage.

Advantages of Acrylic Tubes in Pet Cage Design

Transparency: The transparent design of acrylic tubes allows pet owners to observe their pets at any time, enhancing interaction and making pets feel more secure.

Durability: Acrylic tubes possess high impact resistance and durability, protecting pets from injury and effectively preventing damage to the cage.

Ventilation and Flexibility: The flexible design of acrylic tubes can create a well-ventilated environment and multi-level activity spaces to meet the needs of different pets.

Ease of Cleaning: The smooth surface of acrylic tubes makes them easy to clean and maintain, helping to keep the internal environment hygienic and promoting pet health.

The application of acrylic tubes in pet cage design offers a higher quality living experience for both pet owners and their pets. By combining transparency, durability, and flexible design, pet cages made from acrylic tubes can meet the practical needs of pet owners while providing a safe, comfortable, and healthy living environment for pets. As people’s care for pets continues to increase, the use of acrylic tubes in pet cages is expected to become more widespread, contributing even more to the happiness of pets.

Related FAQ

How to Choose the Right Materials?

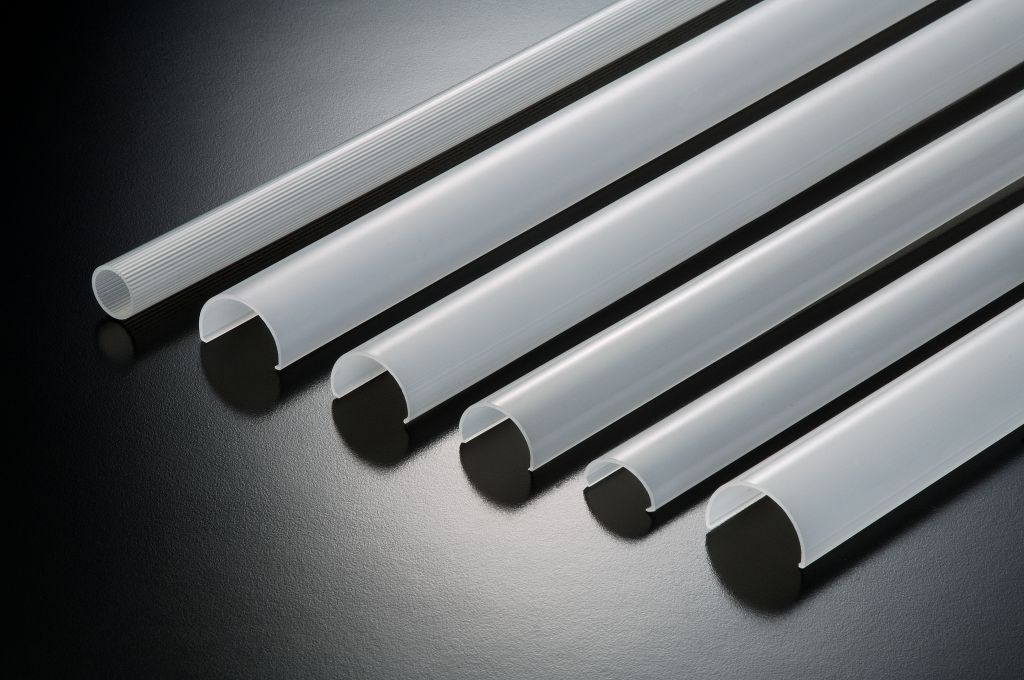

SMEACRYLIC packaging

Is acrylic environmentally friendly?

Acrylic Extruded Tube VS. Cast Tube

PMMA VS. PC

What is Acrylic (PMMA) ?

Related Applications

.jpg)